Animation library for compass 3d v15. • Free libraries. Fig. 121 Selecting a bolt in the Fastener window

Program version: 16.1.3

Official website: ASCON

Interface language: Russian

Treatment: included

Type of medicine: replacing files

System Requirements:

- MS Windows 10 (32 or 64 bit)

- MS Windows 8 and above (32 or 64 bit)

- MS Windows 7 SP1 and higher (32- or 64-bit)

- MS Windows Vista SP2 and higher (32 or 64 bit)

- MS Windows XP SP3 (32-bit)

- Required amount of free hard disk space:

- for installing the Basic package - 1.6 GB (for x86), 1.5 GB (for x64)

- for installation of Machine-Building configuration - additional 700 MB (for x86), 800 MB (for x64)

- for installing the Building configuration - additional 1.8 GB (for x86), 1.8 GB (for x64)

- for installing the Instrumentation Configuration - additional 200 MB (for x86), 200 MB (for x64)

Description:"Compass-3D" is a three-dimensional modeling system that has become the standard for thousands of enterprises due to the successful combination of ease of learning and ease of work with powerful functionality for solid and surface modeling. The main feature of the product is the use of its own mathematical core and parametric technologies developed by ASCON specialists. The main components of KOMPAS-3D are the actual three-dimensional modeling system, universal system automated 2D design KOMPAS-Graph, and a specification design module and text editor. All of them are easy to learn, have a Russian-language interface and a help system.

- functionality for creating and working with designs for parts and assembly units, with subsequent automatic receipt of documentation (specifications and drawings with views and tables of designs);

- taking into account tolerance for all control dimensions in sketches and construction operations;

- mechanisms for working with large assemblies: layers, partial loading of components, special optimization methods that allow working with complex projects that include tens of thousands of subassemblies, parts and standard products, as well as working with layers in 3D;

- functionality for modeling parts from sheet material- commands for creating a sheet body, bends, holes, louvres, collars, stampings and cuts in a sheet body, closing corners, etc., and also performing a development of the resulting sheet body (formation of an associative development drawing);

- special features that facilitate the construction of casting molds - casting slopes, parting lines, cavities according to the shape of the part (including setting shrinkage);

- tools for creating custom parametric libraries of standard elements;

- the ability to obtain design and technological documentation: the built-in KOMPAS-Graphic system allows you to produce drawings, specifications, diagrams, tables, text documents;

- built-in reports on product composition, including custom attributes;

- the ability to set dimensions, designations and technical requirements in 3D models (support for the GOST 2.052–2006 standard “ESKD. Electronic product model”);

Unicode standard support; - integration tools with various CAD / CAM / CAE systems;

- means of protecting user data, intellectual property and information constituting commercial and state secrets (implemented by a separate software module KOMPAS-Zashchita).

- "Compass-Spring" - spring design system;

- "Pipelines 3D" - pipeline design system;

- “Cables and harnesses 3D” - 3D modeling of electrical cables and harnesses and production of design documentation for them;

- “Metal structures 3D” - automation of standard work on the design of frames and frames from rolled metal;

- "Compass-Electric" - design of electrical circuits;

- “Standard Products: Fasteners” - includes 2D and 3D fasteners according to GOST, OST 92, ISO, DIN;

- "3D molds";

- “3D library of parts and die assemblies”;

- “3D library of mold parts”;

- "APM FEM" - strength analysis system for "Compass-3D";

- The main conceptual and most anticipated novelty by users was “mirroring”, which radically changes approaches to 3D design. Mirror designs of assemblies and parts, mirror reflections and texts, new types of mates - now you only need to spend a few clicks to model a symmetrical part of any product or object. The principles of “mirroring” are also implemented in the functionality of preparing drawings. Thus, when adding a view from a mirror version of the model to an associative drawing, inscriptions are automatically generated in the format recommended by GOST 2.113-75. For construction design, KOMPAS-3D has commands for working with text: in the new version you can not only adjust the number and location of characteristic points for moving the inscription, but also, if necessary, create a mirrored text. “Mirroring” tools will be in demand by a wide variety of enterprises and in a variety of areas of application of KOMPAS-3D, because almost all products and objects created by an engineer contain symmetrical elements: from Uralvagonzavod tanks to Aerovolga NPO aircraft, from the Tver company’s fire fighting equipment “Fire systems” to anti-aircraft missile systems of the Almaz-Antey Air Defense Concern...

- Mechanical engineering

- In KOMPAS-3D V16, the developers gave a second life to sheet metal bending, since many ASCON customers use complex sheet-shaped parts in their products. Now available to users wide range commands for quickly creating bends without using additional operations and additional constructions in the sketch. Particular attention was paid to working with ruled shells, which are based on a general ruled surface and are not always physically unfoldable without plastic deformation. Previously, the user was forced to build such parts using surfaces and solid operations without the ability to create a flat pattern, but V16 provides special functionality for this. Designers also have some other types of work with sheet bodies, for example, segmentation by the number of segments, by length, height or angle of a segment in conventional shells, which is necessary when, for example, in production it is not possible to bend a variable radius, i.e. form conical folds. When using these and other new products for sheet metal modeling, it becomes very simple to obtain a pattern of parts and transfer it to equipment, with the help of which it will be cut out of the sheet and subsequently be bent.

- Among other innovations that will be of interest to any machine builder are the preservation of the assembly unit as a body, which makes it much lighter and allows subsequent operations to be carried out more quickly; automatic adjustment of drawing formats when printing; development of the functionality of the “Service Tools” application, which was replenished with a whole set of commands that increase ease of use and speed of execution of standard constructions.

- For the release of the new version, the Equipment: Metal structures application was completely updated. High speed of construction, simplicity, convenience, interactivity - with the new application you can easily and intuitively design complex frame and enclosing metal structures and, as a result, avoid additional costs for materials, tools, and most importantly - loss of time. The application will be useful to all enterprises that use profiled metal products in their products.

- Optimization calculation of cylindrical gears has appeared in the Shafts and Mechanical Transmissions 3D application. It provides a choice of the best solution, reflecting any combination of criteria: strength, wear resistance, smoothness, etc. Also, using the application, you can solve the inverse problem of designing a cylindrical gear - selecting the parameters of the gear depending on its operating conditions.

- Users will also notice how the scope of the Mechanics: Springs application has been expanded. In particular, it adds the ability to construct springs without performing calculations. This is useful when an engineer has a drawing of a spring, but no model: it can be generated by entering geometric parameters using the application.

- Instrumentation

- The Equipment: Cables and Harnesses application has made a significant leap in operating speed. The time for generating a 3D model of a harness has decreased by 3-5 times, depending on the complexity of the harness. Now the designer has the ability to read the composition of connections from the KOMPAS-Electric system thanks to the exchange XML file. This function allows you to automate as much as possible the process of constructing connection routes and harness/cable models.

- New items have also appeared in KOMPAS-Electric itself: a new solution in the preparation of documentation in KOMPAS-Electric (applies to circuits from E3 to E6) makes it possible to increase the information content of documents. And when marking a potential node, you can now include the designation of the harness and cable that includes the specific connection between the devices.

- With the release of 3D CAD Renga Architecture, ASCON does not stop the development of the KOMPAS-3D construction configuration and applications that make up the MinD design technology. Changes in the new version greet the user right from the door: the application interface now allows you to configure tools that can be combined into compact panels and placed in any convenient place on the workspace. At the same time, changing the application automatically changes the set of tools, so each designer can create an individual workspace.

- A list of new materials has been added to the catalog of the Metal Structures: KM application in accordance with the product range; angles, I-beams and channels according to foreign standards appeared. In the filter window, both the GOST for the material and the grade of the material are now available, which will help you more accurately select the required profile.

- In applications of the family of engineering systems - Technology: TX, Life support: OV, Life support: VK - new options have been implemented: Auto-tee, Concentric auto-transition, Eccentric auto-transition, Auto-insert with selection, Auto-insert with transitions. The ability to insert an automatic transition (concentric or eccentric) when changing the diameter has long been lacking in KOMPAS-3D. Until now, this was carried out by selecting a transition element from the catalog, but now it happens automatically.

- Auto-insert with selection is able to find a standard size that is suitable for control parameters (diameter, SDR, etc.) in the same section of the catalog from which the current standard size is selected. On the Catalog Panel, you can select values from the available filters, then automatic selection will be made taking into account the recorded values. During construction, a phantom image of the selected standard size is displayed. Also interesting is the Auto Insert with Transitions mode, which allows you to insert the current standard size and, if necessary, select the desired transition.

From points No. 2, 3 and 4, you can choose only those in which you will work; you don’t have to check everything.

Screenshots:

KOMPAS-3D- a 3D modeling system that has become the standard for thousands of enterprises, thanks to the successful combination of ease of learning and ease of operation with powerful solid and surface modeling functionality that solves all the basic problems of users.

The main components of KOMPAS-3D are the 3D solid modeling system itself, the KOMPAS-Graph universal computer-aided design system and the specifications design module. All of them are easy to learn, have a Russian-language interface and a help system.

Description:

The KOMPAS-3D installation package consists of three parts:

- The basic part of the KOMPAS-3D installation package (hereinafter referred to as the “Basic package”)

- Mechanical engineering configuration for KOMPAS-3D (hereinafter referred to as the “Mechanical engineering configuration”)

- Construction configuration for KOMPAS-3D (hereinafter referred to as the “Building configuration”).

Basic package contents:

- Main modules:

- KOMPAS-3D

- COMPASS-Graph

- Specification design system

- Text editor

- Textbook "ABC COMPASS"

- Manuals for working in KOMPAS-3D

- Drawing fonts

- Software protection systems against unauthorized copying and use HASP SRM

- Development tools (SDK)

- Libraries:

- Text converter eCAD-COMPAC

- eCAD-KOMPAS data converter library

- Function graphing library

- Application library KOMPAS

- Template manager

- 3D model recognition system

- KOMPAS-Macro

- Document verification

- Library Materials and Assortments

- Library Units of Measurement

- Library package “Welds”

- Format import libraries:

- PDF (P-CAD)

- model (CATIA 4.x)

-IGES

- DWG

- DXF

- Libraries for exporting to formats:

-IGES

- DWG

- DXF

- Example libraries

Composition of the Mechanical Engineering Configuration:

- Animation library

- Library of grooves for KOMPAS-3D

- Workshop layout library

- Library for calculating dimensional chains

- Gearbox library

- Library of standard fasteners for KOMPAS-3D

- Library Standard Products: Fasteners (includes 2D and 3D fasteners according to GOST, OST 92, ISO, DIN)

- Library Standard Products: Parts, assemblies and structural elements (includes 2D and 3D: bearings and machine parts, parts and fittings of pipelines, parts of pneumatic and hydraulic systems, parts and assemblies of vessels and apparatus, elements of machine tools, as well as electrical devices and fittings 3D)

- Electric motor library

- Library of elements of hydraulic and pneumatic circuits

- Library of elements of kinematic schemes

- Library of elements of machine tools

- Cables and harnesses 3D

- Design library

- Metal structures 3D

- Package of libraries for the aerospace industry

- System for modeling bodies of rotation KOMPAS-Shaft 3D

- Design system for bodies of rotation KOMPAS-Shaft 2D

- KOMPAS-Spring spring design system

- Pipelines 3D

Composition of the Building Configuration:

- Library for constructing patterns of elements of air ducts and pipelines

- Library for the design of reinforced concrete structures: KZh

- Library for the design of buildings and structures: AC/AR

- Engineering systems design library: TX

- Engineering systems design library: OV

- Engineering systems design library: VK

- Metal support design library

- Metal structures design library: KM

- Library for designing electric lighting systems: EO

- Library of SPDS symbols

- Library of pipeline fittings

- Catalog: Architectural and construction elements

- Catalog: Reinforced concrete structures

- Catalog: Rolled metal assortments

- Catalog: Standard metal structures

- Catalog: Metal structures assemblies

- Catalog: Construction machines and mechanisms

- Catalog: Technological equipment and communications

- Catalog: Elements of heating and ventilation systems

- Catalog: Elements of water supply and sewerage systems

- Catalog: Elements of power supply systems

- Catalog: Elements of vessels and apparatus

- Catalog: Elements of chemical production

- Catalog: Fire and security alarm elements

- Catalog: Elements of structured cabling systems

- Catalog: General plan and landscaping objects

- Catalog: PIC/PPR objects

- Catalog: Wooden structures

- Catalog: Evacuation plans

- KOMPAS-Object

- KOMPAS-Object Editor

- Construction site manager

Minimum system requirements:

CPU: Pentium III, 800 MHz and higher

Memory: 512 MB and above

Video card: 32 bit

Name: Compass-3D V12 (RU) x32/x64 + Add. packages (construction, mechanical engineering)

Year of manufacture: 2010

Platform: Windows XP/Vista/7

Interface language: Russian

Activation|reg code: Present

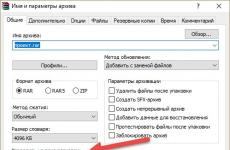

Added 5% archive recovery

files are interchangeable

In the previous article we talked about the importance of application libraries in the development of modern modeling systems. In particular, readers learned about the capabilities of the design libraries of the KOMPAS-3D system and could evaluate to what extent the use of such applications facilitates the everyday work of an engineer.

This article outlines where to start creating your own libraries to make design decisions more accurate and design faster, easier, and more convenient.

As already noted, no single set of libraries for a graphics system can cover all the many different areas and industries and fully satisfy the requirements of all categories of users. The range of problems of design and technological preparation of production has become so wide that solving some of them using both standard and applied tools provided by the software developer company can take too much time and be irrational, and in rare cases even impossible.

A huge list of areas of CAD application is the first reason why any of the modern CAD systems should be as open as possible and must contain tools for creating a package of user libraries. The second reason is customer focus. If, for example, the vast majority of enterprises using a particular system work in mechanical engineering, and a few work in the production of medical equipment, then developers of application libraries are forced to adapt to the first category. But for KOMPAS customers there will be no problems - they can create libraries on their own.

We list the main ways to create libraries:

Creating a library of fragments (sketches) or models based on basic capabilities KOMPAS-3D systems;

Creating a template library using the Template Manager;

Using a special macro environment KOMPAS-Macro to prepare a custom application;

The use of KOMPAS-Master tools, that is, the actual writing (programming) of libraries.

Which of these options should you choose? It all depends on your goals and your idea of the future library: what it should be, what it will do (create, edit, perform any other actions), how powerful and flexible its functions should be. Great value has also the level of your training as a developer. Simple libraries do not require almost any special knowledge, but they also provide few opportunities. Creating more complex modules is impossible without some skills and experience (sometimes from a completely different subject area, in particular programming), and the more complex the library being designed, the more deep knowledge necessary. The complexity of the library here should be understood as the level of automation of those design solutions that will be implemented in the application being created. But don't think that the most automated library is always the best solution. Overly automated applications leave little room for initiative or opportunity to vary decisions.

Creating Fragment and Model Libraries

To create libraries of this type, you do not need any special skills other than the ability to work in KOMPAS-Graph or KOMPAS-3D. With the help of such libraries, each designer can systematize his set of most frequently used elements to facilitate access to them when developing new drawings or models.

Creating your own library of fragments is not difficult at all. To do this in the window Library Manager you need to use the context menu command Add a description > Document Libraries. In the library open dialog box that appears, select the file type: KOMPAS-Fragment Libraries(*.lfr) if you are creating a repository for drawings or sketches, or KOMPAS-Model Libraries(*.l3d) to fill the future library with 3D models. As a result, your library should appear in the Library Manager window, still empty. Once launched, you can add fragments and models to it using context menu commands.

The main advantage of fragment libraries is that they are easy to create and use. A big advantage of such applications is that when new versions of KOMPAS appear, there is no need to adjust or change their structure to fit the newly released release. Just upload the old library file to the Library Manager, and you can rest assured that everything will work.

The disadvantage of such libraries is that they are limited functionality. Automation of such libraries is achieved only by parameterizing the objects with which you fill the application, and the library only speeds up the process of searching and inserting the desired graphic element into the document and provides better conditions for storing them (not in separate files scattered across the hard drive, but in an orderly manner, in single file-library).

The KOMPAS-3D template libraries have greater capabilities compared to fragment libraries.

Creating Template Libraries

The template library is an application library consisting of a basic parameterized drawing or three-dimensional model, a table of variables typed in accordance with certain rules in the MS Excel spreadsheet editor, and a diagram of the KOMPAS-3D document or drawing containing the names of the variables. The library is a file with the *.tlm extension, with the help of which the variables of a parameterized fragment or part are assigned values entered in an Excel table. To create template libraries, there is a special application called Template Manager.

The development of a template should begin with the creation of its prototype (fragment or part), using standard means KOMPAS-Graph or KOMPAS-3D. Then you need to parameterize the drawn fragment or sketches of the model and assign as external all the variables that you plan to enter (type) in the Excel table. The next step is to create a table of values. Such a table is generated in the Excel editor and includes the names of external parameterized variables, visibility flags for value columns in the Template Manager, specific values or their interval for each variable, etc. You can find detailed rules for filling out tables for templates in the help file and examples supplied along with a library of templates. Forming another component of the template - the parameter scheme - will not cause any particular difficulties. The diagram can be any graphic file of the KOMPAS-3D system or a picture file in *.bmp, *.gif or *.jpg format.

When all three components discussed above are prepared, they need to be assembled into a single application. To do this, using the command New library, you should indicate the name of the future library and the folder where it will be located. Next, you need to design the internal tree structure of the library, that is, the sections and subsections in which the templates you have prepared will be located.

The final stage of preparing the library is filling the sections with the appropriate templates, for which you should use the command Create a template. After calling it, a small window will appear in which for each template you need to enter a name, specify a file with a parameterized fragment or model, an Excel parameter table file and a splash screen (optional). Upon completion of all these steps, the template library is completely ready for use. You can load a specific template, enter variable values, and insert the finished part or fragment into the document.

What are the significant differences between template libraries and fragment libraries? First of all, this is the ability to insert into a document not the entire fragment, but its individual layers, as well as the presence of a number of discrete values for a variable, which eliminates the user entering or selecting erroneous values. In addition, template variables can be of various types, including logical and string, and in the dimensional inscriptions of a blank fragment it is easy to reserve variables for text substitutions (they should be highlighted on both sides with a # sign). The main advantage of template libraries is that when using a template, you do not have to manually change parameterized variables, as would be done when inserting a fragment or model from a fragment library. When inserting an object into the active document, the Template Manager itself will take care of inserting the necessary values from the series selected by the user.

Of course, it takes more time to develop templates, and the skills of working with COMPASS alone will no longer be enough; you will have to study the principles of the Library Manager. But the use of templates makes it possible to quite flexibly automate the creation of standard elements and at the same time does not prohibit dynamically managing the process of creating a library element.

Couplings generated using an application developed in the KOMPAS-Master environment

Creating custom libraries using KOMPAS-Macro

KOMPAS-Macro is an environment for developing design applications integrated into the KOMPAS-3D system based on the Python programming language. Why was Python chosen as the basis? Firstly, Python is distributed free of charge and, as a result, does not impose any restrictions on the use and distribution of programs written in it. Secondly, today Python is one of the simplest and most understandable programming languages, but for all its simplicity, it is not much inferior to such “pillars” of object-oriented programming as C++ and Object Pascal (Delphi).

At its core, KOMPAS-Makro is a regular library that connects to KOMPAS, only with O greater opportunities. When creating applications in KOMPAS-Macro, you can use both the functions of KOMPAS-Master (we will talk about them later) and special functions of the macro environment that facilitate the development of application libraries. Among the special functions of KOMPAS-Macro, we should note the functions of setting angular, linear and radial dimensions, the function of inserting a fragment into a document, drawing a leader line, etc. The syntax of the listed methods is much simpler than their analogues implemented in KOMPAS-Master (for example, instead of calling one -the only function for creating a linear dimension in KOMPAS-Macro, when working with API functions of the KOMPAS-Master environment, you have to declare and initialize as many as three interfaces).

If you are familiar with the basics of object-oriented programming firsthand and you have a desire to develop the most powerful libraries based on KOMPAS-3D, then you can use KOMPAS-Master.

KOMPAS-Master

KOMPAS-Master... Agree, it sounds somewhat mysterious. Makes me think of a utility like the CD Burning Wizard in Windows. But it turns out that everything is much more serious.

KOMPAS-Master is a very powerful tool for developing applications (libraries) of unlimited complexity operating in the KOMPAS-3D environment. With the help of KOMPAS-Master, the application programmer gets access to all functions of the system without exception. That is, absolutely everything that the user can do manually, be it creating or editing a graphic document, opening and closing files, working with specifications, creating tables, designing drawings, saving files in various formats, inserting pictures, etc. etc. all this can be automated using KOMPAS-Master.

Access to the internal functions of KOMPAS-Graph and KOMPAS-3D is provided in two ways:

Through export functions, designed as DLL modules, which the developer connects to his program, when creating flat drawings; through the use of COM objects in the software generation of solid models;

Using Automation technology, implemented through the API (Application Programming Interface) of the KOMPAS system. Management and interaction with the system is done through IDispatch interfaces.

The use of IDispatch interfaces is possible in any of the most common programming environments today (Visual C++, Delphi, C++Builder, Visual Basic). Integration with such powerful software packages allows, in addition to the use of KOMPAS graphical tools, to use all the advantages of modern object-oriented programming in the created modules.

The last picture shows three-dimensional assemblies of four different types of couplings (gear, elastic pin-and-pin, torus-shaped with a rubber shell and longitudinal-rolled), in which at first glance there is nothing unusual. Nothing, except that all these couplings are completely generated programmatically using a design library developed in the KOMPAS-Master environment. Their creation consisted only of the user selecting the diameter of the shafts to be connected and clicking the “Build” button. All other operations are hidden inside the program.

But all this power of KOMPAS-Master comes at a price. Unlike libraries of fragments or templates, in this case you cannot get by with knowledge of COMPASS only. To program libraries, you need to be able to clearly formulate the problem: what will be solved using the application being created, imagine all the possible ways to solve it (to create the correct algorithm), and also master the techniques of working with one of the above-mentioned programming environments in order to program everything correctly. An application CAD developer must be both an engineer and a programmer, and at the same time have considerable patience. You need to be prepared to spend time and nerves on difficult debugging of programs. Even if you are a high-class professional, errors are not excluded, and finding and eliminating them can be no less long and tedious than the process of writing a library.

But, having overcome all these difficulties, you will receive a convenient and flexible application with functionality and interface that fully meets your requirements. The program can be made to “think”: independently select, analyze and process the necessary data, perform certain actions depending on the read values, make complex calculations and conclusions based on their results, etc. And all this in order to make the engineer’s work as easy as possible, to save him from performing routine operations.

Conclusion

We have finished the story about a set of various applications for the KOMPAS-3D system. The main goal of this review is to show the importance of application libraries for improving the quality and speeding up design in general and using KOMPAS-3D in particular. Considering that standard libraries cannot always satisfy all users, the articles examined various ways for the designer to create his own applications - from simple utilities to complex modules with powerful functionality.

Surely experienced KOMPAS-3D users know and actively use these capabilities. This material will help systematize their knowledge about the system and its applications. This article will also be useful for young specialists in design and technology departments, who are often experts in the selection and implementation of CAD systems. We hope that the above information will be taken into account when making important decisions and generating new ideas and will ultimately contribute to improving the quality of the designed products.

Design libraries and tools for their creation in the KOMPAS-3D system

Part 1. To help the designer libraries, calculation modules and reference books KOMPAS-3D

Maxim Kidruk

Often, disputes arise between users of various 3D modeling software packages, both domestic and foreign, about which system is better. Everyone is trying to prove that it is the one that he himself uses, since it provides the designer with the largest selection of functions and methods to achieve the goal as quickly as possible. As a rule, such disputes are limited to attempts to convince the opponent that using such and such a system it is possible to build such and such a part easier, faster, with fewer operations, etc. etc. But that’s not the point!

Today, the class of a three-dimensional graphics editor is determined not only by the set of commands offered to the user for creating and editing three-dimensional models or drawings, and not even by the capabilities and functions of each individual command, since the basic approaches to creating models (extrusion, rotation, sectioning, etc.) and their implementation in most modern engineering modeling systems differ little from each other.

That's why the most important characteristic Any modern CAD system, along with modeling tools, is able to automate the processes of creating standard elements and their subsequent use using various auxiliary tools. This, firstly, presupposes the presence of subsystems that expand the standard capabilities of the program, which make it possible to speed up the design of the object itself (unit, mechanism, building), and not its individual part or component. Most often, such subsystems are plug-in modules (libraries) that function only in the environment of the “parent” graphic editor and allow, based on its basic functions, to quickly create and use various standard elements. Secondly, the user should be given the opportunity to replenish such subsystems, taking into account the specifics of a particular industry. After all, no matter how large and professional a team of software developers is, it is still not able to cover all existing areas in mechanical engineering, construction, and energy and satisfy the diverse needs of customers.

It is obvious that the quality of any 3D engineering modeling program is determined by more than just the basic tools. Often, just the opposite: the more separate diverse applications that speed up the development of drawings and documentation, the higher the system is rated by customer enterprises.

The purpose of this article is to highlight a wide range of such applications for the Russian solid-state parametric modeling system KOMPAS-3D, which allow the designer to solve problems of the highest level of complexity.

First of all, you should consider design library, without which no engineer can do, no matter what he designs. The library contains more than 200 parametric two-dimensional images of various typical engineering elements: bolts, screws, nuts, rivets and other fasteners, bearings, profiles, structural locations, pipeline connection elements, cuffs, etc. (Fig. 1). It is also possible to create and place ready-made fastening connections (packages) on the sheet, consisting of bolts (screws or studs), nuts and washers, which further speeds up the creation of assembly drawings. A library element can be easily edited, moved around the drawing, or changed its angle; Moreover, the element does not need to be removed from the sheet or from the fragment if you want to replace it with another. It is important that any parts created using the design library are closely related to specification design module. Consequently, there is no need to manually fill in a huge number of columns containing information about the assembly fasteners; the library will do all this itself.

Great assistance in automating design and engineering work is provided by gearbox library(Fig. 2). The appendix includes drawings of two types of serial gearboxes: helical (one-, two- and three-stage) and worm (one- and two-stage). The library includes very convenient system search, with the help of which in a matter of minutes you can select a gearbox with the necessary parameters and assembly option and insert it into the drawing in any projection. The module is based on an extensive database, which contains not only full information about the characteristic parameters of gearboxes (gear ratios, overall dimensions, nominal torques, etc.), but also information about manufacturing plants, which saves specialists from searching in the catalog for the gearbox selected and inserted into the drawing.

The reducer library is rarely used separately from electric motor libraries, containing images and technical data of asynchronous electric motors of alternating and DC(Fig. 3). For each engine brand, the library contains data on power, rotation speed, efficiency, mass and diameter of the output end of the shaft. In addition, brief information about the development company and manufacturers is provided. specific models electric motors. The image of the engine inserted into the drawing fully corresponds to the overall and mounting dimensions of the product given in the catalogs of the manufacturing companies. As in most other libraries of the KOMPAS-3D system, the libraries of gearboxes and electric motors provide the ability to automatically transfer information about drawn products to the specification.

Rice. 4. 3D models of fasteners created using the fastener library

Considering all of the above, it is easy to imagine how a complex of these two libraries can help the designer when designing electromechanical drives.

All tasks that the design library solves in 2D are distributed among several applications in 3D modeling.

For assembly drawings, some of the functions of the design library are taken over by fastener library(already mentioned). It contains three-dimensional parametric models of all main fasteners: bolts, screws, nuts and washers, covering more than 60 GOST standards (Fig. 4).

The section of structural elements in 3D is presented library of grooves. Its purpose is to create grooves and grooves on the outer and inner cylindrical surfaces of three-dimensional solid models. The designer can add grooves of various shapes to his models (rectangular, trapezoidal, spherical), as well as standardized ones for sealing rings, grinding wheel outlet, cutter outlet, etc.

The groove library is used in its work by a system for the design and three-dimensional solid modeling of bodies of rotation and mechanical transmissions KOMPAS-Shaft 3D without a doubt, the most powerful auxiliary module created by ASCON for working with three-dimensional models. A simple and convenient interface, a wide range of functions that allows you to build shaft stages of various configurations (bevel, cylindrical and polyhedral), a built-in module for calculating external and internal gears, the results of which, with the click of just one button, you can get a ready-made 3D model of a spur gear, all this makes Shaft-3D indispensable when creating mechanical engineering assembly drawings of any complexity and purpose. All models calculated and created using this module are available for editing using standard KOMPAS tools. The result of the application is shown in Fig. 5. The construction of the shaft shown in the figure did not take even two minutes; the splines, keyway and center hole are also generated using KOMPAS-Shaft 3D.

An analogue of KOMPAS-Shaft 3D for two-dimensional design is KOMPAS-Shaft 2D library(not quite two-dimensional, by the way; you can also generate three-dimensional models using Shaft 2D). The Shaft 2D module provides parametric construction of drawings of spline, threaded and keyed sections on model steps, construction of shafts and bushings, cylindrical and bevel wheels, worm wheels and worms (Fig. 6). Using this library, other structural elements can be created: grooves, grooves, grooves, flats, etc. This library, like KOMPAS-Shaft 3D, includes a mechanical gear calculation module that performs geometric and verification calculations of all known mechanical gears (cylindrical and bevel gears, chain, worm, belt). And most importantly, Shaft 2D supports communication with KOMPAS-3D, providing the ability to automatically create three-dimensional models based on constructed drawings. Thus, without any special effort on the part of the user, it is possible to obtain, for example, models of pulleys for belt drives or sprockets for drive chain drives from their flat drawings (the drawing itself, of course, is also created with KOMPAS-Shaft 2D tools). A well-thought-out way of communicating with the user through short dialogues and a well-developed help system help the user quickly master both KOMPAS-Shaft 3D and KOMPAS-Shaft 2D.

Another powerful and multifunctional calculation application of the KOMPAS-3D system is spring design moduleKOMPAS-Spring. Agree that creating assembly drawings or three-dimensional assemblies of high complexity, with a large number of springs, brings a lot of trouble to the designer. In this case, springs may not be the most important elements of an assembly or assembly drawing. This question arises very acutely when creating three-dimensional models of helical springs. Not only does the creation of such a seemingly insignificant part take a lot of time, especially when the number of working turns is not an integer, which is why you have to adjust the placement of cylindrical spirals for the support (pressed) turns on both sides of the spring, but there are also such modifications that cannot be immediately simulated. The KOMPAS-Spring library easily solves these problems, providing design and strength calculations of tension and compression springs, conical and shaped springs, disc springs and torsion springs. Calculations are made in accordance with GOST 13764-86, GOST 13765-86 and GOST 3057-90, and their results can be recorded in a file or used for subsequent construction of drawings or models. A distinctive feature of the library is the ability to vary the spring parameters to obtain the best result, and it is guaranteed that the design calculation will produce several versions of springs with the lowest weight and the best strength criteria for the entered initial data (Fig. 7). In addition to two-dimensional drawings, in which you can automatically add dimensions, construct detailed views and create deformation or force diagrams, KOMPAS-Spring can also generate three-dimensional models for almost all types of springs (Fig. 8).

It is impossible not to mention two more important applications from the arsenal of application programs of the KOMPAS-3D system, expanding its capabilities when designing technological equipment, 3D stamp parts library And 3D library of mold parts. The modules contain solid parametric models of dies and mold parts, most often used in cold stamping and in the design of molds for in various ways manufacturing of parts (casting, pressing).

Much has already been written about the use of these two libraries (this issue of the journal also contains an article on this topic), so we won’t repeat ourselves; Needless to say, what a help they are for the design engineer of technological equipment.

Libraries of models of stamps and molds, like other applications of the KOMPAS-3D system, actively use in their work the library of materials and assortments, which will be discussed further.

When preparing design documentation, the engineer needs information about the materials from which the assembly parts will be made. Without accurate information about the physical, physical-mechanical, chemical properties, heat treatment methods, purpose and scope of application of the material specified in the product documentation, the release of any product becomes impossible. Library of materials and assortments(or its corporate version directory “Materials and Assortments”) is an extensive database containing the specified information and intended for centralized storage and use of this information in various departments of the enterprise (Fig. 9). The differences between a library and a reference book are that the library is local; it does not operate in network mode, and in addition, it only works with a database Microsoft format Access. In all other respects the applications are identical.

The library of materials and assortments contains the strength characteristics of a large number of steels of various grades and their alloys, solders, fluxes, plastics, rubber and leather, adhesives, varnishes, paints and many other materials. With its help, you can select the required material or other object from the directory according to several criteria: by purpose, properties, name. The application has the ability automatic search substitute materials with the display of operational information about the conditions for replacement, if the selected material does not suit the user in some way or is impossible to obtain. It will not be difficult for experienced users to create their own sets of materials. This will avoid confusion when preparing documentation and releasing products. If necessary, you can add new materials to the database or adjust the properties of existing ones.

Information selected from the library of materials and assortments is transferred for use in other applications, and these can be not only software products ASCON companies (KOMPAS, VERTICAL, LOTSMAN:PLM), but also other common CAD systems.

Another useful reference book developed in ASCON laboratories to simplify the processing and use of information about standardized elements, reference book of standard products, created on the basis of an object-oriented approach to modeling and is a convenient tool for creating a single workspace for standard products in an enterprise. The directory provides access to generalized and organized data about standard products and allows the designer to select a specific product both from a general list and according to specially defined classification principles that facilitate search from a specific workplace, with subsequent use of the selected element in an integrated external program (KOMPAS, VERTICAL). The selected element can be used in models, drawings, fragments or specifications, although if desired, the reference book can also be used as a stand-alone application. As in the directory of materials and assortments, here you can create your own packages from frequently used products for later quick access to them. The directory of standard products can work with almost any of the database formats popular today, and its availability at the enterprise significantly reduces the time for searching and processing information by specialists from various services.

In addition to design application libraries and information reference books, the KOMPAS-3D system has several more applications for integration with other graphic systems. For any 3D solid modeling system, the ability to exchange data with other CAD systems used by customers is of great importance.

When designing and calculating particularly complex and large objects (vehicles, power units), some engineering companies often use several software packages at once, and for them the task of data exchange is very relevant, and the ASCON company pays great attention to solving it. Reading is possible in KOMPAS-3D graphic files DXF, DWG and IGES formats; you can open and write model files in STEP, IGES and Parasolid formats; There is separate application library for supporting the model format (CATIA), for reading MODEL files of the CATIA 4 system in KOMPAS-Graph. For example, you can easily import a model or surface created in Solid Edge or Unigraphics and use it in an assembly.

But all this is not enough, since models created by other designers and in other systems are not always suitable for your assembly. They often need to be edited before use. You can, for example, edit the model in the “parent” editor, save it again and then transfer it to KOMPAS. But if the designer’s workplace does not currently have the graphic editor in which the model was created, then it can be edited using KOMPAS. However, since the model does not have the basic operation, sketches, etc., this task becomes difficult and is sure to be time consuming. And in this case, another plug-in module for KOMPAS-3D can provide significant assistance to the designer 3D model recognition system.

The main purpose of this application is to recognize the elements of a part imported into the KOMPAS-3D environment and create its three-dimensional analogue generated by the KOMPAS modeling tools, that is, to display the construction tree for the imported part. The system is focused on recognizing parts of medium complexity, taking into account certain restrictions: bodies with faces formed by NURBS surfaces are not recognized, bodies of revolution must have an angle of 360°, extrusion operations must not have a slope, etc. But even if it cannot display everything correctly operations, then sketches whose parameters could not be fully determined will still be displayed. This will allow you to finish the part manually without any problems.

An example of how the 3D model recognition system works is shown in Fig. 10, which shows a model of a roller overrunning clutch hub: on the right created in one of the three-dimensional graphics editors and opened in KOMPAS through the STEP format (an operation without history in the construction tree), on the left a recognized part with a fully formed construction tree. Although the operations themselves and their order in the tree are far from optimal solution, but recognizing such a part (which took only three to four seconds) is much easier than creating it yourself, as they say, from scratch. Moreover, during recognition, all sketches are parameterized, after which you can easily change and edit the part configuration.

The libraries and applications listed above are not all that the KOMPAS-3D system makes life easier for an engineer. There are many other applications that are included as standard or distributed separately and are aimed at application in various industries. These are, in particular, libraries of pipeline fittings, design of ventilation systems, energy equipment, instrumentation and automation, architectural elements, elements of electrical devices, metal structures design system, etc. The list of them can be very long...

But that's not all - KOMPAS-3D has an extensive set of libraries, distributed free of charge and solving a wide range of different tasks - from drawing axial lines to modeling complex 3D assemblies. All these modules were created and provided by those users of the system who developed them for their own needs and then decided to make them public. You can download these libraries from the website technical support www.support.ascon.ru (Fig. 11).

The site presents diverse libraries that can be divided into two groups. The first is libraries of fragments (both parameterized and non-parameterized), filled with images of various devices and equipment. Second, design libraries are usually small in size and perform a limited number of operations with drawings or models, but are often very useful.

As examples of the first group, consider the library of fragments “Elements of pipeline fittings”, consisting of images of valves, nipples, conical inch threads and pipes, a library of fragments of elements of pneumatic hydraulic equipment, worm gearboxes, electric motors, etc. (http://download.kompas.kolomna. ru/public/libs/Raznoe1.zip), as well as a library of fragments of images of pumps, gearboxes, track switches, etc. Some images from these libraries are shown in Fig. 12.

But the most interesting and useful of free applications, posted on the site, are the libraries of the second group. Created by users, they automate or extend standard tools graphic editor, conveniently customizing them according to the needs of the designer.

In particular, the “Text on Curve” library provides good opportunities, which can create a “text” object in KOMPAS-Graph, using any curves as guides. It can be used when designing architectural drawings or when applying free-form text logos to a designed part. In Fig. Figure 13 shows a three-dimensional inscription created in KOMPAS-3D using this library.

Equally useful is the small Size for Reference utility, which allows you to add a “*” symbol after the size labels for a group of selected sizes, so you don’t have to edit each size individually.

The “Change Text Height” utility will help you save a lot of time when designing drawings, with which you can change the font height for several selected text objects at a time.

The latest addition to the site is the “Autoraskraska” module, designed for working with KOMPAS-3D three-dimensional assemblies. With it, you can easily change the colors of assembly parts by its levels or by selecting a part by name. This application is indispensable for working with already formed large assemblies.

It is worth noting, however, that some of the design libraries from the technical support site were created for KOMPAS version 5.11. Naturally, when trying to connect them to more later versions the system will report an error about the incorrect structure of the library file. But here we can’t do anything: since libraries are non-commercial, the appearance of their updates for each new release of the system depends only on the desire of their creators.

Well, it's time to take stock. It is safe to say that any design and modeling system that claims to be modern cannot be considered a system high level without a solid baggage of plug-ins that deeply and comprehensively expand its standard toolkit. KOMPAS-3D has such baggage. In addition, the system provides a large number of ways to expand capabilities through new applications created by the efforts (and resources) of customers to solve the atypical profile problems that arise before them. A large number of free libraries developed by consumers and posted on the technical support site is undoubtedly proof of this.

Aren't you interested in what these methods are? What do you need to know, where to start, to create your own application for KOMPAS-3D? In the next part of the article we will try to answer these questions.

Compass 3D- Designed to create three-dimensional associative models of individual parts and assembly units containing both original and standardized structural elements. Also present in the assembly Also present in the assembly libraries, catalogs And drawings..

Compass 3D

Year/Date of Issue: 2011

Version: V13

Bit depth: 32bit

Vista compatible: full

Windows 7 compatible: full

Interface language: Russian

tablet: Present

System Requirements: MS Windows 7\XP\Vista

Build Size: 4522.98 MB

Compass 3D

Designed to create three-dimensional associative models of individual parts and assembly units containing both original and standardized structural elements. Parametric technology allows you to quickly obtain models of standard products based on a once designed prototype. Numerous service functions facilitate the solution of auxiliary design and production maintenance tasks.

Composition of the installation package KOMPAS-3D V13 SP1:

Installation package KOMPAS-3D consists of four parts:

- The basic part of the KOMPAS-3D installation package (hereinafter referred to as the “Basic package”)

- Mechanical engineering configuration for KOMPAS-3D (hereinafter referred to as "Mechanical engineering

configuration")

- Instrument-making configuration for KOMPAS-3D (hereinafter referred to as “Instrument-making

configuration")

- Construction configuration for KOMPAS-3D (hereinafter referred to as the “Building configuration”).

Basic package contents:

- Main modules:

- KOMPAS-3D

- COMPASS-Graph

- Specification design system

- Text editor

Tutorials:

- “ABC KOMPAS-3D”

- “ABC COMPASS-Graph”

- Manuals for working in KOMPAS-3D

- Drawing fonts

- Software for protection against unauthorized copying and

using HASP SRM

- Development tools (SDK)

Libraries:

- APM FEM, strength analysis system for KOMPAS-3D

- Library for auto-arrangement of position designations

- Library Units of Measurement

- Library Materials and Assortments

- Function graphing library

: Fasteners

(includes 2D and 3D fasteners according to GOST, OST 92, ISO, DIN)

Library Standard Products: Parts, assemblies and structural elements

(includes 2D and 3D: bearings and machine parts, pipeline parts and fittings,

parts of pneumatic and hydraulic systems, parts and assemblies of vessels and apparatus, elements

machine tools)

Library Standard Products: Electrical apparatus and fittings 3D

- KOMPAS-Macro

- Document picker

- Template manager

- Library package “Welds”

- Application library KOMPAS

- Document verification

- 3D model recognition system

Format import libraries:

- model (CATIA 4.x)

-IGES

- DWG

- DXF

- Libraries for exporting to formats:

-IGES

- DWG

- DXF

- Example libraries

Composition of Mechanical Engineering Configuration:

- Animation library

- Workshop layout library

- Library for calculating dimensional chains

- Gearbox library

- Electric motor library

- Library of elements of hydraulic and pneumatic circuits

- Library of elements of kinematic schemes

- Design library

- Metal structures 3D

- System for modeling bodies of rotation KOMPAS-Shaft 3D

- Design system for bodies of rotation KOMPAS-Shaft 2D

- KOMPAS-Spring spring design system

- Pipelines 3D

- 3D Molds (includes 3D Express Molds)

- 3D library of mold parts

- 3D library of stamp parts

- Mold designer libraries

- Stamp designer libraries

- Coupling library

In addition to libraries, the Mechanical Engineering Configuration contains some utility

KOMPAS-3D in mechanical engineering

design.

Composition of the Instrument-Making Configuration:

- eCAD-KOMPAS data converter library

- PDF support library (P-CAD)

- Cables and harnesses 3D

- KOMPAS-Electric

- KOMPAS-Electric Express

In addition to libraries, the Instrument-Making Configuration contains some service

files required for use KOMPAS-3D when designing

radio-electronic equipment, instruments and electrical equipment.

Composition of the Building Configuration:

- Tutorials:

- “ABC KOMPAS-Graph (construction)”

Libraries:

- Library for constructing patterns of elements of air ducts and pipelines

- Library for the design of reinforced concrete structures: KZh

(includes Catalog: Reinforced concrete structures)

- Library for the design of buildings and structures: AC/AR

(includes Catalog: Architectural and construction elements)

- Engineering systems design library: TX

(includes Catalog: Technological equipment and communications, Catalog:

Elements of vessels and apparatus, Catalog: Elements of chemical production)

- Engineering systems design library: OV

(includes Catalog: Elements of heating and ventilation systems)

- Engineering systems design library: VK

(includes Catalog: Elements of water supply and sewerage systems)

- Metal support design library

- Metal structures design library: KM

(includes Catalog: Rolled metal assortments, Catalog: Units

metal structures, Catalog: Standard metal structures)

- Library for designing electric lighting systems: ES

(includes Catalog: Elements of power supply systems)

- Library of SPDS symbols

- Catalog: Rolled metal assortments

- Catalog: Elements of vessels and apparatus

- Catalog: Construction machines and mechanisms

- Catalog: Fire and security alarm elements

- Catalog: Elements of structured cabling systems

- Catalog: General plan and landscaping objects

- Catalog: PIC/PPR objects

- Catalog: Wooden structures

- Catalog: Evacuation plans

- Gas supply design system: GSN

- Rubius Electric Suite: power lines 0.4-10 kV

- Rubius Electric Suite: MZ

- KOMPAS-Object

- Construction site manager

In addition to libraries, the Construction Configuration contains some service files necessary for use KOMPAS-3D in industrial and construction design.

Drawings for mechanics in the Compass program

Assembling drawings for the specialty “Construction machinery and equipment”.

Installation:

Apply the patch after installing the "Engineering Configuration", otherwise there are no files for patching.

In 64-bit operating system:

1. Run KOMPAS-3D_V13_antiHASP_v1.0.exe as administrator. Click "Apply".

2. A window pops up

click "YES".

3. Find Materials.exe (it is located: C:\Program Files (x86)\ASCON\KOMPAS-3D V13\Libs\Materials\Materials.exe) and patch it.

4. And so on.

In a 32-bit operating system, all files are located automatically.

Launch the program, go to Tools -> Options -> General -> System Management -> check the box "Automatically obtain a license to work in Compass 3D".

Restart.

To use the "Directory of Materials" you need to manually specify the path to the Matsort.mdb file:

- after launching MaterialsCfg.exe, specify the path there (even if it is specified) and click check. There should be a message that the connection is successful and that’s it.