DIY repair of household appliances and electronics. Self-repair of household appliances. Where is repair needed?

Repairing household appliances is quite possible with your own hands, but this is not always possible, since modern devices very complex technical parameters and finding a fault is not as easy as it might seem at first glance. It is worth noting that household appliances are an important component of every home, and it is simply impossible to do without them. It is hardly possible to imagine a person who washes his own clothes, cooks food over a fire, or heats water using an iron cup rather than a kettle.

Advantages of professional equipment repair from specialists

Repairing electrical appliances is quite difficult, since there are an incredible number of models, brands and types of products. Each device has a specific electrical circuit, which a beginner is not always able to understand.

To restore the operation of a gadget that is so necessary for the home, experts recommend contacting an organization such as an electronics workshop.

There are a number of advantages to collaborating with experienced people, which are worth getting acquainted with before the equipment is even more damaged when repairing it yourself. Technician service centers offer comprehensive diagnostics, through which even the slightest malfunction can be detected.

Advantages:

- Detailed advice is provided regarding the breakdown, method and cost of repair, as well as how to avoid such a situation and operate the product correctly.

- Service centers provide installation of only original spare parts, and the use of budget parts is possible only with the client’s permission and when drawing up paperwork.

- The service center provides professional service, as only qualified specialists are hired, which emphasizes the prestige of the center.

- After repairing any household appliance, the device is configured, adjusted and calibrated so that the customer can receive the installation fully operational and suitable for use.

Service at the service center provides the opportunity to obtain a warranty and repeat free repair, if the breakdown occurs precisely because of the technician’s oversight. Carrying out repairs from a specialist will be much faster than searching for diagnostic devices yourself, as well as parts for resuming work.

Reasons for repairing electrical appliances

What to do if electrical equipment breaks down, and is it possible to repair it yourself? If visually the outlet does not raise any suspicion, then you need to connect any other device to this connector. As soon as there is evidence of its serviceability, you need to look for the cause in the equipment.

You should not immediately go to the service, as it is advisable to check a number of trivial points, for example:

- Serviceability of the socket;

- Availability of food;

- Correct connection.

Due to the fact that in in this case If you are considering a washing machine, you need to check the access to water or simply whether the water supply tap is open. Due to its overlap, the device will block operation.

Maintenance and repair of household appliances may require certain training, work experience and, of course, diagnostic devices, which only specialists in service centers have.

Depending on the type of equipment, in particular its dimensions, it is possible to carry out diagnostics and repairs at home, if the breakdown is not too complex. It is important to note that if household appliances were purchased quite recently and malfunctions began to occur, then it is strictly forbidden to independently enter the housing and carry out any actions, as this automatically voids the manufacturer’s warranty. It is best to contact the store where the device was purchased and request warranty diagnostics, which is free.

Preparing to repair household appliances yourself

Modern advanced technologies are what make up new generation household appliances, but even such devices can fail. The main reasons for the malfunction of electrical appliances include some problems.

Namely:

- Voltage overload;

- Jumps in current supply;

- High room temperature;

- Presence of vibration or shock during product operation.

If a malfunction occurs and the object refuses to work, then you need to look for the cause in the electronics after a series of preliminary actions. Testing of items such as lamps, fuses, switches and similar parts is required.

The power supply and power unit are checked by using a voltmeter, through which the voltage at the input and output is examined.

It is advisable to additionally check the serviceability of the sensor, signaling device, limit switch, monitor, kinescope and speaker system, if you are checking the TV or speakers.

Household electrical appliances: causes of breakdowns

To repair any type of home appliance, it is not enough to learn to understand the details, since you need to become familiar with what malfunctions occur most often. Some of them include:

Namely:

- Open circuit;

- Increasing resistance for no reason;

- Significant reduction in resistance;

- Availability short circuit.

There are common reasons why they occur. An open circuit may be due to old age of the elements through which increased current passes, as well as shock, vibration and corrosion. Resistance increases in the electrical network also due to the aging of elements or simply loss of their proper appearance.

This contributes to the deterioration of contact connections and to deviations from the desired parameters.

Reducing resistance in electrical circuit may occur due to increased surface leakage and aging of parts. A short circuit occurs due to breakdowns in insulation, as well as when a wire or element is short-circuited and the integrity of its body is damaged.

In Moscow you can meet various companies, websites and even such a service as a private master, through which it is possible to repair household appliances. However, in order to save money, you should try to find the fault yourself, which can be done by following a number of recommendations below.

- An intermediate voltage measurement is carried out, due to which it is possible to monitor whether the signal is correctly passing to different channels in the system.

- It is necessary to exclude those parts of the device that are working properly, which will reduce the number of breakdown options, and provide the technician with specific data. This helps reduce diagnostic costs.

- If you replace a unit that may have a malfunction, the probability of eliminating the breakdown increases to 80%.

- It is necessary to evaluate the serviceability of a serviceable circuit and a faulty circuit in order to determine which parameter requires intervention and maintenance. This requires special diagnostic equipment.

The troubleshooting process consists of certain stages, the sequence of which cannot be broken. The fact of device failure is established. This is not difficult to do, since the device will refuse to perform its direct duties. It is required to analyze emerging problems and compare them with possible problems described in the manufacturer's instructions.

A full diagnosis of the device is desirable, since the cause of an external breakdown may lie internally, and without special equipment it is simply impossible to determine it.

It is necessary to determine the extent of the damage and decide whether maintenance will be carried out independently or with the help of a specialist. Sequential testing of each element connected to the control module is carried out. A general assessment of the device malfunction is made. Problems are being fixed.

How to repair an electric waffle iron and other appliances with your own hands

It is quite possible to repair an electric waffle iron or electric samovars yourself, but an electrical household appliance requires accuracy, clarity, and maximum caution. The most important thing is to examine the device only after disconnecting from the power supply. First you need to familiarize yourself with the principle of operation of the device.

When diagnosing, you should study the most complex parts of the device, and only then begin diagnosing smaller components. A fault analysis is carried out, during which it is necessary to determine the type of repair and its benefits. To ensure the accuracy of the results obtained, it is best to double-check each part of the device for serviceability. Experts recommend visually dividing the equipment into several parts and checking each module separately, which will reduce the time spent searching for a breakdown. If the fault is not too big and self-repair is possible, then you should do it yourself.

Repair of household appliances (video)

In some cases, breakdowns may be of such a nature that it is easier to purchase a new device than to repair an old one. Such recommendations can only be given by experienced specialists after a thorough diagnosis. If you do not have the skills to work with electrical appliances, then it is better to entrust it to professionals to avoid even bigger problems.

Electronic modules of washing machines are the most complex parts of this household appliance. They are based on a printed circuit board, on which the control elements for each unit of the washing machine and its parts are located in a special order. The microprocessor, the most expensive part of the control module, synchronizes the operation of the elements. Electronic modules of modern washing machines can break down, and this is where the main problems begin. In this article we will discuss these problems and outline ways to resolve them.

How can you tell if a module is broken?

The most basic problem is to understand whether the control module is actually broken and needs repair, or whether one of the units of the washing machine is actually broken, and it is this that creates the appearance of damage to the electronics. Permission this issue has priority, because if you start immediately repairing or changing the module without sufficient reason, you will throw money down the drain and the problem will not be solved.

Therefore, first, let’s figure out how to diagnose a problem with the electronic module? Let's start with something simple - let's study the typical signs of an electronic module failure. In approximately half of the cases, the electronic modules of modern washing machines, by their “behavior,” reveal the cause of the malfunction. All we have to do is recognize and identify it.

- , in this case the control panel freezes and does not react in any way to user actions, the error code is not displayed on the display.

- All the lights on the control panel flash together and alternately, and it is not possible to start any washing program.

- The washing program is set and started, but water either does not fill the tank, or the water immediately drains on its own, and after this the machine freezes “tightly”, only a reboot can save it. In this case, after restarting, washing can be carried out in normal mode.

- With any washing program, the machine washes for 3-4 hours in a row without stopping, without switching to rinse and spin mode. The drain pump makes no attempt to remove water from the tank. After a long time, the machine freezes.

- After turning it on, when trying to set the washing program, the machine freezes and immediately turns off.

- The washing program is set, the washing progress is displayed on the display, but in reality nothing happens, water does not pour into the tank, the drum does not spin - nothing happens.

- The motor changes the speed of rotation of the drum unreasonably often, even if the change in speed is not caused by the program. The drum rotates alternately and for a very long time in one direction and then in the other.

- The heating element of the washing machine either overheats the water or leaves it cold, ignoring the readings of the temperature sensor.

Important! The indicated behavior of the washing machine only hints at a malfunction and future repair of the electronic module. To be sure, it is necessary to conduct a series of tests.

Each of the eight above signs of breakdowns can indicate either a malfunction of the control module or a malfunction of one of the sensors or the washing machine unit. To make sure that it is indeed an electronic module, You must first run an autotest of the washing machine, and then test the machine units manually. Only after this can final conclusions about the malfunction be made. So, how to do an autotest of a washing machine?

Each of the eight above signs of breakdowns can indicate either a malfunction of the control module or a malfunction of one of the sensors or the washing machine unit. To make sure that it is indeed an electronic module, You must first run an autotest of the washing machine, and then test the machine units manually. Only after this can final conclusions about the malfunction be made. So, how to do an autotest of a washing machine?

On different models Washing machines autotest is done in different ways. Therefore, we recommend that you carefully read the operating instructions for your model of automatic washing machine. Let's give an example of self-testing using the Ardo washing machine as an example.

- We move the programmer arrow to a strictly vertical position, so that the arrow points down.

- Set the temperature to zero.

- We check that the drum is empty and there is no water in the tank.

- We press all the buttons on the control panel at the same time, after which the machine’s autotest mode should start.

Upon completion of the test, the display should display an error code corresponding to either a malfunction of the washing machine unit or a malfunction of the electronic module.

Pay attention! The test cannot be performed in washing machines, in which it is installed asynchronous motor, or on ultra-modern machines, with a built-in self-diagnosis system (there is a special button on the “self-diagnosis” panel).

Autotest does not produce adequate results in all cases. To verify that the electronic module is faulty, you need to test it with a multimeter. The same must be done with all suspicious units, ringing them one by one. The work, of course, is very painstaking, but this is the only way to be 100% sure that the electronic module is faulty.

Why does the control module break down?

There are many reasons why an electronic module may fail. And not all reasons are due to improper operation of the washing machine. But first things first.

- Factory defect: one of the parts of the board or track is damaged.

- Ingress of moisture, work in conditions of very high humidity.

- Voltage fluctuations.

- Turning off the washing machine several times electrical network during the washing program.

Factory defects, unfortunately, are typical for both cheap and expensive washing machines.

Most often, such defects occur in the most complex part of the washing machine - the control unit. Fortunately, in most cases the problem is identified in a short time, when the machine is still under warranty, but sometimes the problem manifests itself only after several years. In this case, repairs have to be carried out at your own expense and often with your own hands.

Any automatic washing machine is designed precisely in such a way as to operate in very harsh environmental conditions, especially high humidity. Nevertheless, in some cases, it is moisture that causes failure of the electronic module. Basically, moisture causes a short circuit that damages electrical and electronic components. After this, the machine will definitely need serious repairs.

If you connect a washing machine to a “protected” electrical network, a voltage drop may well burn out any unit of the washing machine or all units together, including the electronic module. This can be avoided if you include a difavtomat in the electrical communications that power the washing machine.

And finally, the user factor. Never forcibly disconnect the washing machine from the power supply while it is running. Several such shutdowns may well damage the electronic module. If you urgently need to turn off the washing machine, it is better to press the stop button, and only then turn it off - this will be less harmful than a sudden shutdown.

We fix it ourselves or call a specialist: which is more profitable?

Now let’s move on to the main question: is it worth repairing the electronic module yourself or is it better to entrust this important task to specialists? It is quite difficult to answer this question. Everything will depend on your knowledge, skills and abilities in working with microcircuits and printed circuit boards, as well as on the nature of the breakdown.

The most basic problem for an amateur is identifying a breakdown in the electronic module. Each part needs to be ringed, a burnt element or a broken track must be identified, and only then the element must be replaced or the track soldered. The likelihood that you will do everything right, having mediocre skills, tends to zero.

Of course, it is possible to replace the electronic units of modern washing machines, but this will not give anything, especially if high-quality diagnostics have not been carried out. The new electronic module board will most likely burn out again.

There is another option - remove the entire control unit and give it to a technician for testing. Experts do not recommend doing this. If you invite a technician, then you need to give him the opportunity to call and check the control unit locally, right on the washing machine. This way he is able to identify the problem more accurately.

Important! Electronic modules of modern washing machines can only be repaired by qualified technicians; do not trust repairs to just anyone, ask for the recommendations of a specialist before entrusting him with the work.

Whatever one may say, it is more profitable to contact a specialist. Repairing such a complex element of a washing machine yourself can lead to even greater costs. In the worst case, if you carry out an incorrect test of the equipment, you can burn not only the control unit, but also the heating element, motor, drain pump, or all at the same time - you will have to buy new car. This raises the question - why take the risk? Isn’t it better to entrust the repair of your home assistant to a good craftsman?

Troubleshooting electronic circuits. In this article we will look at how to independently find and fix simple breakdowns in electronic circuits. Let's say we have a portable cassette recorder that has stopped showing signs of life, doesn't turn on, doesn't respond to button presses, and the LED indicator doesn't light up. In this case, the search for the cause of the malfunction should begin with the power supply.

It’s good if we have an external power supply, in which case we turn on the power supply to the network and measure the voltage at the plug (output from the power supply) with a multimeter. For low-power household audio equipment, it is usually sufficient to select the 20 volt DCV limit on the multimeter, or in other words, the DC voltage measurement.

If you need to repair high-power audio equipment, then the output from the power supply may have a voltage significantly higher than 20 Volts. In this case, you need to select a voltage measurement limit of 200 volts, also DCV. If there is no voltage at the output, you will have to disassemble the power supply housing, or if the power supply is internal, the entire device. In this case, you need to check, first of all, the fuse in the primary winding circuit of the transformer.

Fuse

Sometimes, as in the diagram below, fuses are installed additionally in the secondary winding circuit. You need to ring them by setting the multimeter to the audio dialing mode, you need to simultaneously touch the metal tubes - the contacts at the ends of the fuse. In this case, it is not necessary to remove the fuse from the metal racks on the board; it is enough to touch them with the probes of the multimeter; if a sound signal is heard, this means that the fuse is intact. Otherwise, the fuse has blown and must be replaced with a new one rated for the same current.

Although, if the device uses transformer power, you can first check the integrity of the fuse, and at the same time the cord, by setting the multimeter to the resistance measurement mode at a limit of 2 kiloOhms and touching the probes of the multimeter to the pins of the power cord plug. In this case, we get, as can be seen in the figure below, the power cord wires, the fuse and the primary winding of the transformer are connected in series.

In this case, the multimeter should display a reading of about 300 Ohms. This means that the supply wires, fuse and primary winding of the transformer are in good condition. If your device has a power button, you should press it before performing this test. You can also “click” the power button during such a test; when you turn it on, the multimeter screen will show a reading of about 300 Ohms, when you turn it off, one or infinite resistance.

Transformer - photo

If, with such dialing, the cord does not ring through, you will have to disassemble the case and ring the cord and transformer separately. I don’t think anyone will have any difficulties with checking the cord, one probe is for the plug, the second is for the wires entering the housing of the device; I described the continuity of the cord in detail in the previous article. Those terminals of the transformer that are connected to the wires through which power comes are the primary winding. You can ring it by setting the multimeter to 2 kilo-ohm ohmmeter mode, the resistance should also be about 300 Ohms.

You can also distinguish the primary winding from the secondary by the thickness of the wires; the primary is usually wound with a wire of a much smaller cross-section than the secondary, due to the fact that currents flow in the secondary winding, greater than in the primary. The picture above shows a transformer with several secondary windings. The resistance of the secondary winding of a transformer when tested with a multimeter is close to zero, due to the fact that the number of turns of the secondary winding is much less than in the primary, and accordingly, when tested, the resistance will be much less than in the primary.

If the primary winding does not ring with an ohmmeter, and accordingly such a transformer does not work, then do not rush to throw it away; a thermal fuse is usually installed under the insulation near the terminals of the primary winding, as in the figure above. It is triggered when heated above the set temperature and breaks the circuit of the primary winding. Like a regular fuse, a thermal fuse is used only once, after which it may need to be replaced. You can check it with an ohmmeter or multimeter in audio testing mode. Often, after replacing the thermal fuse, if the windings are intact, the transformer can continue to function as before. It is not uncommon for a diode bridge to burn out. As you know, a diode bridge consists of 4 diodes connected to each other using a special bridge circuit.

As can be seen in the figure above, the diode bridge has 4 connection points, 2 points are supplied AC, and going to the load plus and minus. On a real diode bridge, these points are each connected to their own output; these are 2 outputs alternating current and plus and minus.

Photo - diode bridge

This is what we see on the imported diode bridge (+), (AC - alternating current) and (-). In order to check the diode bridge, we conditionally divide it into separate diodes and ring it as if we had 4 separate diodes. To test a diode, you need, as everyone knows, to set the multimeter to the diode testing mode; on the multimeter it is indicated by a diode icon; often this mode on the multimeter is combined with the audio testing mode.

Next, we connect the red probe to the anode or the positive electrode of the diode, and the black probe to the cathode or negative, or in other words, we connect while observing the polarity. In this case, numbers approximately 600-900 should appear on the screen. If a beep is heard or one appears on the screen, this means that such a diode is faulty. When connecting probes in reverse polarity, there should be a unit on the screen.

Everything that is written above about checking radio components applies only to parts soldered from the board. When checking when radio components are soldered into the board, it is necessary to take into account the influence on the measurement results of all parts connected in parallel to those being measured! Let's look at troubleshooting using this simple audio probe circuit as an example:

First you need to conduct a visual inspection of the device to see if there are any blackened resistors or similar defects. The fact is that when resistors burn out, this is most often visible from their appearance. Below is a drawing of the printed circuit board of this probe:

Printed circuit board for sound probe

If there are any suspicious ones;), you need to ring them with a multimeter in ohmmeter mode, identifying them by schematic diagram their denomination. The permissible deviation from the nominal value for imported resistors is 5 - 10%, for domestic MLT type - 20%.

On factory printed circuit boards of various household appliances, a layer of silk-screen printing is applied from the side, reverse printed on the PCB, or in other words, a designation of where which element is and where which pin is soldered. This helps a lot during repairs, without wasting time tracking along the paths, each time, where what part is. On printed circuit boards made by radio amateurs, it is also possible to apply a layer of markings using the LUT method with reverse side fees.

Let's return to our sound probe board, let's say we decided to ring all 3 transistors soldered into the board. Let's start with VT1, since it is a transistor n-p-n structures, we must install the red probe on the base terminal of the transistor, and the black probe alternately on the collector and emitter. In this case, depending on the type of transistor, there will be numbers on the screen of the order of 600-900. If a beep sounds during the test, or one appears on the screen, then such a transistor must be replaced. The pinout will help us determine where the output of the transistor is on the board. Our circuit uses transistors KT315 and KT361. Here is their pinout:

The difference between VT2 and VT1 lies in the structure. In the figure above you can see that the base of the VT2 transistor is n-type, this means that when checking, you need to connect a black probe to it, and alternately a red one to the collector and emitter. Otherwise pnp transistors structures are checked in the same way as n-p-n structures. If the pins are not marked on the board, you need to look in the transistor reference book, or on the page with background information on the Internet. If it is necessary to check non-polar capacitors for short circuits, they are tested with a multimeter in ohmmeter mode. The capacitor terminals should not ring with each other, or in other words, there should be a unit on the screen.

All modern washing machines are equipped with a control module. The more functionality the SM has, the more delicate the electronics: they are more susceptible to breakdowns, since they are sensitive to power surges in the network. Is it possible to repair the “brains” of washing machines with your own hands, and how to diagnose their breakdown, we will find out in this article.

The main control unit of the washing machine is equipped with two boards. One of them is responsible for the operation of all parts of the washing machine. The other ensures the operation of the control panel - buttons, indicators - and has the appropriate connectors for connecting wiring.

Is the board really not protected from overloads in any way? Of course, the manufacturer has provided for such cases surge protector, which takes the hit during a power surge in the network.

How to check the washing machine circuit board and determine the breakdown?

The fact is that most signs may indicate a breakdown of both the module and other parts. For example, you notice that the machine has stopped working and the washing does not start. This may be due to a problem with the module or motor of the washing machine.

What may indicate a malfunction and subsequent repair of the board in the washing machine:

- SMA displays an error code on the display.

- The system is frozen and does not respond to user manipulations.

- It takes too long to wash. The machine either fills or drains water, after which the system freezes.

- The drum suddenly changes direction of movement for no apparent reason.

- The spin mode does not turn on.

- The water overheats or does not heat up, which does not correspond to the selected mode.

However, the next time you start it, the washing machine can work again in its usual mode.

Some SMA models have an autotest that allows you to determine the cause of the breakdown. How to start it is written in the machine's operating instructions.

- A short circuit as a result of a voltage drop can lead to burnout of capacitors, thyristors, triggers and other elements on the board.

- High humidity. If the SM is used in a bathroom, over time, humidity will affect the main unit, which will lead to its malfunction.

- Broken power cord. If the wire is abruptly broken, a voltage surge may occur, which will affect the operation of the module.

- Frequently abruptly turning off the machine from the network can lead to a problem over time.

- Factory defects are less common.

Be careful when transporting SM from place to place. Be sure to remove the powder dispenser as there will be some water left in it. During transportation, water gets on the main unit, which leads to its combustion when connected.

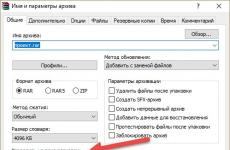

To start the repair, you will need a diagram of the control board of the washing machine, as shown in the example of the Indesit washing machine.

We can advise you to superficially inspect the module to look for burns and damage. There are other methods of checking, but only an experienced specialist can carry them out. If malfunctions are identified, you will have to replace the “brains” for the washing machine.

To conduct a visual inspection, we’ll figure out how to remove the washing machine circuit board. First unplug the washing machine, then do this:

- Pull out the detergent dispenser tray. To do this, pull it towards you while simultaneously pressing the latch in the center.

- Now remove all the screws holding the control panel in place.

- Use a screwdriver to release the plastic latches. Remove the panel from the body.

- The main unit is located behind the panel. Take a photo or mark with a marker the location of the wires. Then disconnect them and remove the unit.

- You may need to release the block latches to get to the board.

Once the board is in front of you, carefully inspect it. Noticed any burnt areas? Then you need to repair the control unit of the washing machine.

We will show you how you can replace some elements. To do this you will need a soldering iron and a new part.

- Capacitor. On the control board it serves as a kind of stabilizer. To replace it, you need to solder the new part to the positive electrode. To find out where which electrode is located, use a tester.

- Resistor. To check the operation of the resistor, a tester is used. 1st order resistors should show a result of 8 Ohms and an overload of 2A. Second-order resistors show 3-5A, while the resistance values depend on the frequency of the module. If the indicators do not meet the standard, the elements are replaced using the soldering method.

- Thyristor block. Check thyristor block can be done by measuring the negative resistance. Indicators should be no higher than 20V. The unit filter could also have burned out. You can repair it by cleaning the cathode.

- Trigger. Testing a trigger involves measuring the voltage of the input contacts. Their performance should not exceed 12 V. The trigger filter resistance should be 20 Ohms. The element is also replaced by soldering.

Soldering of board components may be disrupted due to strong machine vibrations. Therefore, you need to ensure the correct and stable installation of the washing machine.

The master knows how to properly repair the control board. Think before you start repairing yourself, because electronic unit is quite expensive. If you do not have the skills to work with a soldering iron, and the test indicators do not give specific results, contact service center.

For those who have decided to do their own repairs, video

Washing machines, vacuum cleaners, heaters, air conditioners, refrigerators - this is not a complete list of devices without which the life of a modern city dweller would turn into a real hell. People are simply unaccustomed to doing without all this. But household appliances periodically break down, and the question arises of what to do with them. Is home appliance repair accessible to everyone? Let's talk about this.

What will be needed for repairs?

Of course, all electrical appliances are designed differently. Each of them has many nodes that fail for various reasons. Accordingly, in order to fix the problem, you will need different tools. It may very well be that when you decide to repair your air conditioner or washing machine, you will be forced to buy some tools.

Standard set of tools

But there is a certain set that every self-respecting owner needs, unless he is going to run to the service center for every minor breakdown:

- tester (preferably a multimeter);

- screwdriver set different sizes;

- screwdriver;

- pliers;

- chisel;

- sharp knife;

- drill with attachments.

Why is all this needed?

- Testers are needed to determine which elements of the electrical system have failed.

- You can buy screwdrivers separately, but there are many sets of screwdrivers of different sizes on sale, including Phillips ones. So it’s better to immediately purchase a couple of different sets.

- The purpose of a screwdriver is clear - it is needed not only for repairing large-model household appliances, but also for fastening built-in equipment, and is also useful for making all kinds of shelves and cabinets.

- You should not open the wall of the washing machine with a chisel, but in some cases you simply cannot do without this tool.

- A sharp knife is never superfluous.

- As for a drill with attachments, it is not always needed for repairing household appliances, but it can be very useful for attaching it.

Important! In general, you can’t have too many tools, and it’s better if they are always at hand when you need to do minor or more complex repairs of household appliances with your own hands. And so that all these screwdrivers and pliers don’t lie around in the most unexpected places, you can buy a special organizer for them with containers of different sizes and shapes.

What else is useful for repairs?

In addition to the tools, in order to start repairing household appliances with your own hands at any time, it is useful to have:

- fasteners;

- several types of glue;

- masking tape;

- marker;

- camera.

Important! Everything is clear with glue and fasteners, but why do you need a camera? And everything is very simple. Very few people know thoroughly the structure of all household appliances. If you are undertaking any repairs for the first time, it is very important not to mix anything up during assembly and not to leave unnecessary parts. It is best to photograph the location of the elements before disconnecting them; fortunately, modern digital photographic equipment makes it possible to do this without problems.

Take care of your documents!

Each new household appliance comes with instructions. You definitely need to save it:

- If the equipment is from a reputable manufacturer, the instructions describe everything - from the configuration to how to repair the household appliances used.

- When buying equipment secondhand, do not forget to ask the former owners if the documentation has been preserved. This will make your life much easier when you have to change the seal, install a new heating element, or do other repairs to household appliances yourself.

Important! On the Internet you can now find instructions for any devices, including old ones. You just have to make sure that your computer reads formats such as pdf or djvu - it is in them that technical documentation is most often saved, since such formats allow you to place not only text, but also pictures.

What types of repairs are possible for household appliances?

There are problems that anyone can fix, as long as their hands grow from the right place. For example, this could be the following repair of household appliances:

- install a new battery;

- replace the heater and other components;

- change the seal;

- clean filters.

Breakdowns also happen, which it is better not to take on yourself if you do not have the appropriate knowledge and skills. For example, it is better not to repair household appliances yourself:

- If it fails touchpad, it is best to contact a service center, because flashing is possible, which you are unlikely to be able to do yourself.

- Some washing machines will not be able to replace the power cord without a specialist.

In general, in each specific case it is necessary, first of all, to soberly assess your strengths and capabilities.

Where can I get spare parts for repairing household appliances?

In showrooms that sell household appliances from one company or another, they usually also have components. So this is where you should go for a spare hose or a new battery.

Why is this so?

- The manufacturer may have its own standards, and components from other companies may simply not fit your device.

- The company's salon employs people who deal specifically with this brand; they have probably been contacted more than once with a variety of questions regarding the repair of household appliances, so you can count on advice.

- If you have lost the instructions for your device, you can find it in the company showroom, scan it there, or, in extreme cases, transfer it to your camera.

Important! Components from other companies may not only be useless for your device, but even dangerous: if you have to use them, find a correspondence table.

Safety precautions when repairing household appliances

When you decide to take on the repair of household appliances yourself, think not only about putting the equipment in order, but also about your own safety:

- The device must be disconnected from the power supply during repairs.

- The unit must be clean and dry.

- Some types of work when repairing household appliances are best performed with gloves, or even a respirator.

- When working with acids (for example, acetic acid), you need to ensure that drops of the substance do not get into your eyes or mucous membranes.

- Tools, fasteners and generally everything that is needed to repair household appliances must be stored in a place where small children cannot reach.

Why all this?

- When repairing household appliances, you disrupt the electrical circuit; a breakdown can occur anywhere. Therefore, it is necessary to unplug the plug from the socket.

- As for moisture, water is an excellent guide, and if the circuit is broken, you can get a pretty strong electric shock.

- There may be grease on some components, or dirt may accumulate there. Therefore, it is better to always have gloves on hand.

- It is better to remove fasteners so that a small child cannot stick a screw in his nose or swallow a nut. And for electrical appliances, an element that accidentally ends up in the wrong place can be disastrous.

Important! Minor breakdowns that you can handle on your own happen with gas and electric stoves. Useful tips You will find information on repairing these devices in our separate reviews:

How to replace the battery in a quartz watch?

This action refers, rather, not to the repair of household appliances, but to prevention - the batteries in the watch must be changed periodically, otherwise the device will no longer show the exact time.

Important! The quartz resonator operates at a frequency of 32768 Hz. It is located on a microcircuit that looks like a drop, but is actually a semiconductor crystal with wiring filled with a compound.

All schemes quartz watch look the same:

- The voltage comes from a battery rated at 1.5 or 3 V to the switch.

- The switch is connected to the crown.

- The crown is pulled back - the contacts open.

- The voltage is interrupted.

- The clock stops.

When to change the battery?

For most models, the battery is designed to last 1 year; for some branded watches it can last longer – three or even five years. When the battery runs out, the clock starts to lag. Eventually they stop.

Important! Some models have special function, which indicates that the charge is running out - the second hand begins to jump through several divisions.

Table preparation

Before changing the battery, although this is not a full-fledged repair of household appliances, you need to take care of the workplace. The watches have very small parts, and it is very easy to lose something. It’s even worse if a foreign object gets between the teeth of the gears, and it could just be a grain.

To prevent this from happening:

- Wipe the table surface with a damp cloth.

- Spread a large white sheet of paper on it.

Important! Before work, it is better to tuck your hair under a scarf or cap.

Preparing your watch

Even the weakest battery lasts long enough. Over the course of a year, quite a lot of dirt can accumulate in your watch and bracelet. Replacing the battery is a great reason to clean it all up.

But first you need to remove the bracelet, which is attached to the watch using pins that easily fit into the fastening tubes:

- Use an awl or thick needle to hook the protrusion on the pin.

- Press the pin into the strip tube.

- Separate the bracelet from the watch

To then put the bracelet in place, you will need to do the following:

- Insert one pin of the strip into the hole of the eye and press it in.

- Insert the second pin into the second hole.

- Make sure the pins fit neatly into the holes.

Important! Be sure to orient your watch correctly when attaching the bracelet.

Cleaning the watch

It's very easy to do. Simply wipe the watch with a cloth soaked in soapy water and wrung out thoroughly. But the bracelet or leather strap can be washed - in the dishwasher or washing machine. Just remember to put it in a fabric bag. As for the internal details, we covered this topic in detail in our separate article.

Opening the lid

To change the battery, you need to get inside the clock mechanism:

- Find the lid - it is located on the side that comes into contact with your hand.

- Determine the mounting method.

- Remove the cover.

- Remove the battery.

- Place a new one and close the lid.

There are only four ways to attach the cover:

- on screws;

- without fasteners, due to a tight fit;

- on thread;

- using a locking ring.

In the first case, select a suitable screwdriver and simply unscrew all the screws. When you put the cover back, tighten the screws until they stop.

To remove the snap cover, inspect the area where the edges meet the watch body. As a rule, a barely noticeable gap is located somewhere near the bracelet lugs:

- Insert a thin knife or small flathead screwdriver into this slot.

- Gently press the handle, using a sharp object as a lever.

- Remove the cover. The cover, put on the thread or secured with a locking ring, just needs to be unscrewed - with pliers or calipers.

Important! This action should be performed without effort.

Changing the battery

First you need to remove the seal and remember how it was located. It's best to sketch or photograph it. The battery itself is secured with two straps, one of which is fixed. In this case, the movable bar is secured with a screw so that the battery does not fall out at the most inopportune moment:

- Unscrew the screw halfway, thus loosening the bar.

- Move the bar so that it releases the battery.

- The battery should rise up - there is a spring under it.

- Take the battery - preferably with plastic tweezers.

- Take it out.

- Inspect the negative terminal tab (it's in the center of the notch).

- Check the new battery (voltage).

- Remove the sticky layer from the battery.

- Place it in the nest.

- Replace and secure the cover.

The simplest home appliance repair is complete!

We repair the heater

Household heaters come in several types:

- electrical;

- oil;

- convection

Any of them can break down, most often this happens with electrical ones, and first of all it is necessary to determine what exactly has failed. Usually it looks simple: the heater stops heating, and therefore the equipment needs to be repaired.

Important! First, check if there is voltage at the outlet. The circuit breaker at the entrance to the apartment trips quite often, and the sockets break down periodically.

To check the voltage at an outlet, simply plug another appliance into it. You can also conduct a test using a heater that causes you doubts - just connect it to another outlet to understand whether it is faulty or the wiring is faulty.

Once you've determined that the outlet is OK, take a look at the heater itself to figure out what type of appliance repair you need. Pay attention to the position of the switches:

- Plug in the heater.

- Turn the switches to the “on” position.

- Wait a few minutes.

- If the heater does not work, you will have to disassemble it.

We carry out diagnostics

Before disassembling the system and repairing household appliances, conduct an external inspection:

- Inspect the plug that connects the device to the network - it should be intact, without visible defects.

- Inspect the plug pins - they should not be loose.

- Pay attention to the color of the pins - there should be no darkening or scorching.

- Check the integrity of the cord, especially the junctions with the plug and the housing.

- Look through the holes in the panels inside to see if there are any torn or burnt parts.

- Please note that there are no visible mechanical damage on the heating element - this is usually visible through the holes.

- After making sure that there is no visible damage, take a tester or multimeter and set it to low resistance.

- Check the power cord at the junction with the plug by setting the device switch to the operating position and attaching the ohmmeter probes to the pins of the plug.

- Swing the cord from side to side, observing the tester - the slightest deviation of the arrow indicates that the defect is in this particular place.

- Replace the plug.

Heater - inside view

It is possible that the device will still have to be disassembled. To do this, you need to know how it works and on what principle it works.

Important! The simplest option is when the cord and plug are connected directly to the heating element. A more complex option - between the cord and the heater there is a block with terminals; they are connected with threads or slip-on terminals.

Most household heaters have a more complex circuit; they also have a switch. There may also be an option when a fuse is added to the circuit, the task of which is to open the circuit when it overheats. There may also be a sensor that is connected in series with the fuse.

Finally, you may come across a circuit with two heating elements and an additional switch. But in any case, the device is not particularly complicated, and understanding the elements will not be difficult.

Important! The situation is somewhat worse with the fan heater. It has a motor with an impeller, and therefore an additional switch. Expensive models may have other bells and whistles, such as a temperature controller, various indicators, etc.

Disassembling the heater

Disassembly for repairing household appliances should begin from the place where the power cord enters the housing:

- Unscrew all the screws you see on the side panel.

- Unscrew the countersunk screws by removing the decorative plug.

- Open the screw hole that connects the heater cover and base. Unscrew another secret screw - it may be under the seal.

- After removing the side cover, inspect the wires.

- Check all elements with a tester.

Checking the cord

The wire of modern heaters is three-core, colored blue, red and yellow-green:

- Set the tester to resistance measurement mode.

- Connect one probe to the pin of the plug, the second - touch the green and red wires in turn: in one case the resistance should be zero.

- Check the second pin and the second wire in the same way.

- If the wire is ok, measure the resistance between the common terminal and the others, it should be zero.

- Check the thermostat by touching the tester probe to the terminals and turning the knob - the resistance should be zero.

Important! If the thermostat gives any other resistance, remove it by unscrewing the two screws. Heating elements are checked by measuring the resistance between the wires. You should also check the fuse, if there is one.

Changing details

Having found out the cause of the malfunction, decide what to do with the failed element. The best solution is to replace it, fortunately there are no problems with this. In every company store you will find components, and if not, you can order the necessary parts via the Internet.

Important! Before removing parts, do not forget to sketch or photograph their position, especially if this is your first time repairing household appliances. It is best to write down the disassembly sequence - you will have to assemble the heater in the reverse order.

We repair the iron

The design of all heating devices has a lot in common. In this sense, repairing an iron is not much different from repairing a heater.

And in our separate review you will find out.

Diagnostics

The scheme differs slightly, so you will have to proceed in a similar way:

- First, check the condition of the wiring and sockets.

- Inspect the iron. Just like with a space heater, start with the cord and plug. The fork must be absolutely intact, its pins must sit tightly and not dangle, and the screw must be tightened until it stops. Scorches are unacceptable. The cord must be absolutely intact.

- Check the terminal contacts. A faulty power cord is best replaced. Of course, you can wrap it with electrical tape, but this is a temporary measure, and not safe.

You won’t be able to look inside the iron; there are no perforations or meshes in this case. Therefore, if the cord and plug are in order, but the unit does not work, you will have to disassemble it.

Where to start? There are few options. You'll find just a few screws on the back where the cord attaches. They need to be unscrewed to make repairs.

Important! Not every iron can be disassembled. If this does not work, the device will have to be changed completely.

What can be repaired?

The most common breakdowns are oxidation of the thermostat contacts and serviceability of the fuse:

- If the heating element fails, you will have to part with the iron. It is unlikely that you will be able to remove it from the sole - unless, of course, you have an old grandfather’s iron, which can be easily disassembled.

- And the thermostat can simply be changed.

Repairing a kettle

Not every modern kettle can be repaired simply because some models cannot be disassembled.

Important! To find out if your kettle can be repaired, look at the bottom. If you find at least one screw, the kettle can be disassembled.

A kettle is also a heater, only it is designed a little differently than an iron:

- The main part is the heating element, like all heating devices.

- Power is supplied to the connector located in the stand.

- The kettle is connected to the stand via a connector.

- In the vessel itself, in addition to the heating element, there is a switch, an indicator light (for some models) and a thermoelectric relay.

Important! When the kettle is placed on the stand and the switch is turned on, the circuit is closed and the indicator lights up. When the water warms up to a temperature of 100°C and boils, the thermal relay is activated and the circuit opens. If the kettle is faulty, you first need to look for damage to the circuits through which voltage is supplied to the heating element.

Important! The most important source of all troubles with household appliances is scale. Proper care of your equipment can extend its life. And what’s most convenient is that you won’t have to spend a lot of time and money for this if you take note of the methods we’ve proposed

Where is repair needed?

As with the heater, repairs may be required:

- in the cord;

- in a socket;

- in a fork;

- in the connector.

Repairing such household appliances, which you can do yourself, usually comes down to repairing the cord. The wire is checked in the same way as for a heater or iron.

If the connecting circuits, switch or thermal relay are damaged, the device must be disassembled. This is not always possible:

- If the body is not dismountable, repairs should be abandoned.

- If the body is collapsible:

- Remove the screws.

- Ring the circuits and switch the same way you did with the heater.

- Electrically conducting circuits can be restored - soldering or cleaning the contacts, adjusting the switch spring, etc.