Disassembling and repairing a computer mouse. If your mouse is “dead” or repairing a computer mouse yourself. Is it possible to repair a wireless mouse?

Computer mouse- Probably everyone knows what it is. This is a manipulator or a coordinate input device for controlling the cursor and issuing various commands to the computer. Over time, this device develops various malfunctions: damage to the stranded wire, the sensor often malfunctions, the mouse wheel sometimes scrolls, mouse buttons do not work, etc.

Let's look at do-it-yourself repair of the most popular computer pointing device - the mouse!

The mouse is technically a fairly simple device, so it can be quite easily repaired with your own hands. If you know how to handle a soldering iron even a little, this will allow you to fix almost any damage to the mouse. However, even if you are not comfortable with a soldering iron, you can fix some typical mouse damage with a minimum set of tools:

- Phillips screwdriver,

- pliers,

- scissors,

- scotch.

Basic malfunctions of computer mice

Now there are several types of computer mice that differ in the principle of operation (roller, optical or laser), the number of buttons (3 and above), and the type of connection (PS/2, USB or wireless (with USB adapter)). However, the most common are optical ones with a USB or PS/2 connection.

Such mice are relatively inexpensive (not much more expensive than roller mice, but much cheaper than laser ones) and at the same time have fairly high accuracy, which is enough for most users.

| Np.p. |

Description of the problem |

Possible malfunction |

|---|---|---|

| 1 | The mouse does not respond to connection at all | Broken or chafed wires; violation of the integrity of the printed circuit board; controller failure |

| 2 | The sensor is acting up. The cursor jumps or moves jerkily | Optical sensor clogged; LED fault |

| 3 | The scroll wheel does not work or the scrolling area moves jerkily when scrolling | Loosening of the scroll mechanism; drying of the lubricant inside the mechanism; encoder (scroll sensor) defects |

| 4 | A specific button gets stuck or double pressed | Loosening; failure of the button mechanism; problem with settings or mouse driver |

| 5 | A specific mouse button does not work | Failure of the button mechanism |

Disassembly and device of the mouse

We usually disassemble the mouse using a small Phillips screwdriver. To do this, turn the mouse upside down, find and unscrew one or more screws that hold it together. If the screws are not visible, then they are most often hidden under stickers or foot stands:

Usually the screws only hold the mouse in the back. The front part (where the buttons are), most often, is fixed due to special grooves. To remove the top cover from these grooves, you need to lift it slightly by the freed back part and slowly pull it towards you. You can press it a little more from the front, but the main thing is not too hard, otherwise you will break it! The grooves on the top cover of the mouse and the pins that held them in place:

When you remove the top cover, you will find a small circuit board underneath, which is usually only held in place by small plastic pins (although it can also be screwed to the case). Wires (if the mouse is wired), buttons, a scrolling mechanism, as well as a complex of LED backlight and sensitive optical sensor will be soldered to this board:

To completely disassemble the mouse, we need to remove the printed circuit board from it and disconnect the scroll wheel (it can be easily pulled out of the encoder slots).

Wire inspection and repair

Most often, when connected to a computer, the mouse either does not work at all, or twitches or the cursor movement disappears if one of its wires frays or breaks somewhere (unless, of course, the mouse is wired).

A typical optical mouse usually has 4 to 6 wires of different colors. The colors and number of wires depend on the specific manufacturer, however, there is a standard:

Mouse wiring color scheme

Nutrition– red (other options: golden, orange, blue, white).

Receiving data– white (other options: blue, orange, yellow, green).

Data transfer– green (other options: golden blue, yellow, red, blue).

Earth– black (other options: golden green, green, white, blue).

You can definitely judge the correct wiring by looking at the letter markings of the wires in the place where they are soldered to the printed circuit board (unless, of course, they are torn off from the board). Breakage and chafing of wires most often occurs in places where the wire is bent at the exit from the mouse body. You can indirectly check for a break by pulling out the wire and testing it for bending in questionable places (it will be easier to bend at the break point). However, in order to judge for sure, you will have to remove the insulation by carefully cutting it with a blade.

Having discovered a place where the wiring is broken, you need to restore its integrity by soldering or twisting. I personally prefer twisting :) I’ll give a photo of the finished twist, what it should look like:

After splicing the wires, insulate them from each other with electrical tape or tape. You can try it. To avoid burning the port, you need to connect or disconnect the mouse when the computer is turned off! To eliminate any doubts about a break, try ringing all the contacts of the USB (or PS/2) plug using a multimeter. After repair, the mouse should work.

Optical mouse sensor does not work

Often there is also a situation when we cannot accurately move the cursor to a certain point. It constantly trembles and moves on its own. This situation clearly indicates that the optical group of the mouse is clogged. Clogging is most often external. Dust or hair gets into the compartment where the diode light is reflected from the table.

To get rid of such a blockage, you don’t even need to disassemble the mouse. Just turn it over and blow it out. As a last resort, use a small brush to remove stuck debris.

If even after such manipulations the mouse cursor trembles, then, most likely, either the sensor is clogged inside or has completely failed.

In any case, you can try to disassemble the mouse and clean the sensor using a toothpick with a cotton swab soaked in alcohol wrapped around it:

Optical sensor of a computer mouse

Before cleaning the sensor with a cotton swab, you can also try blowing it to remove any fine dust that may stick after it gets wet. After this, carefully, without pressing, insert the toothpick with rotational movements into the sensor hole. After making a couple of turns and without stopping rotating, we take out the toothpick, wait for the alcohol to dry and try to connect the mouse.

If, after all attempts at cleaning, the sensor does not work normally, then if you have another mouse, a soldering iron and straight hands, you can unsolder the non-working microcircuit and replace it with a sensor from another mouse.

Mouse wheel scrolls

It happens that the mouse works fine, but when we try to use its wheel, the page we are scrolling begins to jump up and down, or does not want to scroll at all. Alas, failure of the mouse wheel is a fairly common failure and it was this that prompted me to write this article. First you need to carefully consider how evenly the wheel rotates in the groove. The groove itself and the wheel axle have a hexagonal cross-section, but sometimes one or more sides of this hexagon can become deformed, resulting in the axle slipping in the problem area.

If you have just such a problem, then it can be solved by sealing the edge of the wheel axle with adhesive tape or electrical tape in small quantities. If everything is normal with the movement of the wheel, then the breakdown has occurred inside the encoder (scroll sensor). It may have become loose from prolonged use and should be tightened a little:

We tighten the latches of the mouse scroll mechanism

To do this, take small pliers and press them one by one on the four metal brackets that secure the encoder to the plastic parts of the scroll mechanism. The main thing here is not to overdo it and not break the fragile plastic, but at the same time press harder. Try connecting the mouse and checking whether the negative effect when scrolling decreases after each click. Alas, in my case it was not possible to completely get rid of jerks. Yes, the frequency and spread of page jumps have decreased, but the jumps themselves have not completely disappeared. Then I decided to approach the issue of sealing radically and in a truly Russian way :) I cut out a piece of thin but dense polyethylene from an old battery pack and stuck it inside the mechanism:

Seal inserted inside the mouse scroll mechanism

What’s most interesting is that this manipulation helped! All I have to do is cut off the excess length of the strip and assemble the mouse :)

There are several more options:

- disassemble and clean the mechanism;

- replace the mechanism from another mouse (with a different malfunction).

Mouse buttons don't work

Any button has its own click resource. Usually the contact at the left mouse button disappears. The mouse has several buttons: left, right and under the wheel. They are all usually the same. A non-working button cannot be repaired in any way, but it can be replaced from another mouse.

Bottom view of a soldered mouse button microswitch

The microswitch has three “legs”, the first of which is free, and the other two are contacts that need to be soldered. Sometimes the button still works, but it doesn’t work every time you press it. Such a symptom may indicate that, from frequent use, the edge of the button pusher that presses the microswitch has worn out or there is poor contact inside the contact plate switch.

We disassemble the mouse and carefully examine the problematic button and its pusher. If we see a small dent, then that may be the problem. It is enough to fill the dented area with a drop of epoxy resin or melted plastic. At the same time, while the switch is disassembled, you can clean the contact group.

The last problem you may encounter is that the mouse button makes a double click when you click on it - the so-called contact bounce. This issue can be solved by re-soldering the microswitch or... programmatically!

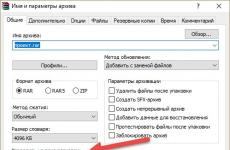

In any case, before you take up the soldering iron, check that the mouse settings are correct in the Windows Control Panel:

Standard mouse properties, what they should be

By default, the double-click speed slider should be in the center, and the sticky mouse buttons option should be disabled. Try setting these parameters and check if the problem is resolved. If not, another radical software way to “cure” a double click is to remove the mouse driver.

Mice– one of the most actively used computer devices. Therefore, it is not surprising that they often fail. However, due to the simplicity of their design, in most cases anyone can fix a mouse! To do this, you don’t need to know how to solder or understand electronics.

The main thing is to clearly diagnose the cause of the breakdown. Here, as in medicine, a correct diagnosis is the path to successful repair. I hope our article will allow you to determine what exactly is broken in your mouse, and therefore, to fix the problem.

Good luck with your renovation!

If the computer mouse breaks down, many users do not know how to continue living. The session ends and the search for a new device or recovery begins performance broken thing. If you have basic knowledge of electrical engineering and the ability to work with a soldering iron, you can very quickly repair a wireless mouse. Let's consider a step-by-step method for determining the causes of a device malfunction and restoring its resource.

Sources of failure

In most cases, the cause of the malfunction will be non-critical, because modern laser mice are being manufactured made from reliable electronic components.

Loss functionality may occur due to:

- damage to the computer's USB connector;

- poor quality contacts in the power and control parts of the board;

- failure of an electronic element;

- microswitch failures.

Repair algorithm

Before starting work, you need to remove the wireless module from the computer, set the mouse switch to the “off” position and remove the battery. It would be a good idea to check the battery right away. If everything is fine with it, then we proceed to repair the mouse.

To determine performance USB computer just connect a flash drive or keyboard to it. If a synchronization signal appears on the monitor screen, it means the port is in working condition. To check the status of a wireless unit with a USB connector, you need to connect similar probes of the tester, which is in diode testing mode, to the positive and negative inputs of the plug. If the multimeter displays numbers from 500 - 700 Ohms, then the module is working. Of course, this method only indirectly determines the condition of the device and does not guarantee one hundred percent confirmation of its serviceability.

In most cases, the activities listed should help you repair mouse . In the rest - the breakdown will be hidden in microcontroller.

Computer mice, as well as computer keyboards, are among the cheapest input devices. Quite often, users who have noticed problems with these devices have the idea of simply throwing this outdated junk in the trash and instead purchasing new high-tech wireless input devices. To be fair, it is worth noting that not all modern wireless mice are highly reliable. Sometimes even the most expensive products from well-known manufacturers refuse to function normally. Lack of response to pressing the left key, inaccurate cursor positioning and many other typical faults of wireless mice can and should be repaired yourself. Within the framework of this publication, a typical problem with the Logitech M205 wireless mouse will be solved - poor response of the left key.

First, the characteristics of the AA element must be measured. This AA battery must have a nominal voltage of 1.5V. If this value is greatly underestimated, then replace the AA element.

Secondly, check the functionality of the optical transmitter-receiver. It's no secret that the M205 wireless mouse emits infrared waves, so the operation of its emitter can only be seen in a video shot on a mobile phone. Cheaper mice emit red light, which is visible to the human eye.

And thirdly, check the quality of operation of the right and left keys. If the sound of pressing the right key is significantly louder and clearer than the sound made by pressing the left button, then this clearly indicates severe wear of the microswitch of the left key. It is because of the defect in the microswitch that you have to press the left button harder and harder. Why does it fail completely?

How to disassemble and repair a computer mouse

First, you need to remove the battery - an AA battery. It is hidden under the top cover. To easily and quickly remove the latter, you will need to press a special button on the reverse side.

Second, turn the mouse over and look for the stickers on the legs. It is under these stickers that two small self-tapping screws are hidden. Take a screwdriver for repairing mobile phones (Phillips head) and unscrew it.

Thirdly, we pry off the latches by prying on the latches.

Fourthly, with a smooth, confident movement, we pull the upper part of the mouse towards ourselves, supporting the base. If you pry a little with a screwdriver, the mouse opens easily.

Fifth, you need to unscrew the single screw that holds the circuit board in place.

The board is also held in place by two plastic clips, which can be easily pressed out with a flat-head screwdriver.

Important tip: Always support the other half where the battery compartment is located. If this is not done, then there is a high probability that the wires connecting them can be easily broken.

Sixth, locate the microswitches on the PCB. Try using a screwdriver to press the microscopic button on both the left and right microswitches. The click sound when pressed should be loud and clear. If this is so, then the switching plate in the microswitch has not yet reached critical mechanical fatigue, and the special arc-shaped loop responsible for returning the button to its original state has normal elasticity. If there is no characteristic clicking sound or it is indistinct, then it’s time to disassemble the microswitch.

How does a microswitch work?

To repair a microswitch you need to at least know how it works and functions. Under the lid there is a complex structure consisting of a thin brass plate with a spring-loaded arc, as well as three complex-shaped plates at the base. In fact, a plate with a U-shaped cutout and a spring-loaded arc is the main switching element in the switch. If for some reason it becomes deformed, breaks or becomes dirty, the switching will not occur incorrectly.

Algorithm for diagnosing and repairing a microswitch

Locate the pins on the back of the circuit board that come from the microswitch. Connect a digital meter (multimeter) to these heels and measure the resistance of the normally closed contact connection in the microswitch. If the device, turned on in dialing mode, beeps, the microswitch is working. If it does not emit any sound signal, but, on the contrary, shows a certain voltage drop, the microswitch is faulty.

Microswitch repair

As a rule, the vast majority of repairmen do not repair switches - they solve this problem by replacing them. Ordinary users may be deprived of this opportunity. It is for ordinary people that simple recommendations for repairing a microswitch will be given.

First, you need to remove the cover. This can be easily done with a slotted screwdriver.

Third, carefully pry off the plate with the U-shaped cutout using tweezers.

Fourth, remove any traces of dirt and oxidation using a fine diamond file. If you don't have a file, you can use as fine a grit of sandpaper as you can find. Then remove microscopic metal shavings using a toothbrush.

And fifthly, treat the contact heels on the plate with either a file or sandpaper. As a rule, they have an oxide film. The final stage is to place the record in its rightful place and close the lid. Important tip: if you have thick fingers, use tweezers to install the plate.

After repairing the microswitch, it is necessary to reassemble the mouse. As a rule, all manipulations must be performed in an order that is exactly the opposite of the disassembly algorithm.

Even the best, high-quality mice tend to get clogged. There are a lot of small crevices in them that even a needle can barely fit through, but dust and hair are placed there comfortably. And occasionally, coffee spills inappropriately on this small device. What to do when the mouse is clogged and the buttons and wheel do not respond as expected? There is only one way out, or rather two: you can easily throw out the mouse, but if this was not part of your plans, you will have to disassemble it mouse .

You will need

- Small Phillips screwdriver, container for storing screws

Instructions

1. Prepare the mouse for disassembly. To do this, disconnect it from the computer and place it on the table, upside down. Locate the mounting screw on the bottom surface of the mouse. The screws are sometimes not immediately visible, because they are often hidden under stickers. In this case, first remove all stickers from the base of the mouse.

2. Carefully unscrew the mounting screws. The screw heads on mice are traditionally cross-shaped, and therefore the same type of screwdriver is required. The screws are located in recesses; it will be easier to remove them with a magnetic screwdriver. It is important that after unscrewing, put the screws in a prepared container, otherwise they will get lost.

3. Open the case. To do this, hold the mouse with both hands on the bottom and top surfaces and pull the cover towards you. Calculate the force so as not to break off the lid latch near the cord. The best thing to do is to pull the lid up and a little to the left. Now you can blow out and clean the insides of the mouse from accumulated debris and dust.

4. Remove the scroll wheel from the base of the mouse. There are various designs for mounting scrollers. Most often, just pull up and the wheel will come out together with its mount or latch. There is often a lot of hair wrapped around the scroller axis. Remove this hair with a suitable tool.

5. Remove the board or mouse chip. The board is secured with latches or screwed. Gently bend the latches with your fingers. Unscrew the screws and put them with the rest of the parts. Lightly pull the board up to separate it from the mouse body. That's it, the mouse parsing is complete.

Occasionally, a computer mouse suddenly loses its functionality. This is due to chafing of the cable near the case itself. In such a situation, you have two options: buy a new mouse or try to repair the old one.

Instructions

1. Disconnect the mouse from the PC. Take a small Phillips screwdriver to disassemble the computer mouse. Find the mounting screws on its bottom surface. Unscrew them using a screwdriver.

2. After this, try to remove the top cover of the case. Pry it with a thin sharp object from the side opposite the cable entrance to the mouse. If the case does not budge, it means there are hidden screws. As usual, they are located under the rubber feet of the mouse. Remove the rubber bands from the holes. Using a Phillips screwdriver, remove the remaining screws.

3. Look under the stickers. There may also be mounting screws hidden there. Please note that damaging the sticker is only allowed if the warranty repair period has expired. Otherwise, it will no longer be possible to repair your computer mouse at a service center.

4. You will save rubber feet from the fact that without them it will be very inconvenient for you to use the mouse. It turns out that in order to disassemble the mouse, remove the upper part of the case. Remove the scroller. Usually it is equipped with a shaft, fixed on one side in a detachable hinge. The other end of the shaft should be attached to the encoder hole.

5. Lift the shaft over the joint and remove it from the hole. Remove all screws holding the board in place. After this, remove the latches. Later, remove the optical cover and lens from the board. Leave the multi-pin connector in its original place. Take wire cutters and cut the wire until it enters the housing.

6. Cut the damaged piece of cable to repair the mouse. After this, clean the contacts. Take a soldering iron. According to the colors of the pins, solder them to the multi-pin connector inside the mouse body. Later, connect it to your computer. See if the LED lights up and if there is a reaction to the rotation of the scroller.

7. After this, you can return the lens to its former place and check if there is a reaction to movement. If the mouse works properly, reassemble it. If not, check the positive solder connections on the multi-pin connector. It is possible that you left a jumper between the contacts.

If you have ever organized a meal at a laptop or the process of cooking near a laptop (there are some), most likely, after these events, your laptop refused to work. Maybe it works, but something from food got under the key. In order to pull out a particle of your previous food from under the key, you need to disassemble the keyboard or remove only the key.

You will need

- Laptop keyboard, tool for removing keys (anything thin and not sharp).

Instructions

1. In order to begin cleaning the keyboard buttons, you need to remove the keyboard. Many laptop keyboards come apart from the keys. In order to avoid mistakes during assembly, it’s best to take a photo of your keyboard or a photocopy. Any key on a laptop keyboard consists of several parts: - key pad; - key lift; - spring element (not present in all keyboards).

2. To quickly complete the process of removing the keys, any thin and non-sharp object can be used: a watch screwdriver, a thin awl, a dental hook. The keyboard button pad is connected to the elevator via latches. Connections can be either movable or non-movable. With support for static connections, the key is detached from the keyboard body. As usual, this connection is located at the bottom of the keyboard button. You need to insert the hook between the static connections, making sure that it goes between the elevator and the landing.

3. So you took one off button. If you need to do the same with multiple keys, be mindful of their placement. Use your photo or a photocopy of the keyboard when reassembling the keyboard buttons.

4. The keys are placed in their former place by completely snapping into place. Put button to its intended place and press it.

Video on the topic

Personal computers have long been impossible to imagine without a keyboard and mouse, which are the main intermediaries in the “communication” between the user and technology. Unfortunately, mice break and start acting up quite often. The computer mouse can be disassembled and cleaned.

Instructions

1. Dirt and dust penetrate into the ball mice better than anyone, getting under the roller. The cursor begins to twitch when moving, or may not move at all in any direction. Therefore, it is very important to use a rug and make sure that dust does not accumulate on it.

2. Disconnect the manipulator from the PC, but only when the system unit is disconnected. The mouse body can be cleaned with a traditional damp cloth and a small amount of liquid soap. But don't even think about washing it mouse under running water. True, after disassembling the optical (precisely optical) mouse, the case itself can be thoroughly rinsed. Primitively, mechanical mice also have a microcircuit that cannot always be removed from the case.

3. Take a small Phillips screwdriver and unscrew the small screw that is located in the recess at the bottom of the manipulator body. Typically the body consists of 2 parts. There may also be a small latch on the side of the screw. Carefully divide the body without using any special force.

4. If the mouse is optical, you need to carefully wipe the glowing scarlet “eye” in its lower part using a match with cotton wool or an ear stick. You can also use a can of compressed air. Carefully remove the huge chip from the optical mouse body and free its plastic parts from dust, dirt and hair (fur). Remove the rubber-covered ball from a ball mouse and wash it with soap or wipe with alcohol. Pay special attention to the mouse wheel and its mountings. Dirt often accumulates there too.

5. To remove dirt mechanically, it is better not to use a knife or razor, but to take a small plastic scraper. Carefully scrape off dirt from its support where possible.

6. Having dealt with dust and adhering dirt, remove grease from the rotating parts of the manipulator. This can be done with a soft, lint-free cloth soaked in alcohol. Also wipe all the insides of the mouse with alcohol to prevent dust from accumulating for longer.

7. It is now allowed to collect mouse. Put the chip (wheel) back and close the case. Be careful not to pinch the wire. Tighten the screw and consider the mouse cleaned.

If, while working at the computer, your hand suddenly and sharply begins to hurt mouse, the pain intensifies and does not go away for a long time, then we can “congratulate” you. This is a manifestation of tunnel syndrome, following the disease of civilization. Severe pain and the impossibility of continuing to sit at the computer may conceal swelling of the tendons and damage to the nerve of the wrist. A chronic form of joint disease may even develop. How faithfully you hold the computer mouse, your health depends.

Instructions

1. Check how you usually hold mouse PC. In order to hold mouse positively, the hand should be straightened and located as far as possible from the edge of the table.

2. Stop using the retractable keyboard and mouse tray. Better yet, pick them up and place them on the table in front of the monitor. The angle of the arm in this case will be closer to 90 degrees, which will be more convenient for you.

3. The furniture on which you sit - a chair or an armchair - must have armrests that will provide the necessary support for your arms and wrists.

4. Mouse pads are not a relic at all, only if there is a special anatomical convexity for the wrist. Using such a mouse is very comfortable and reliable. Therefore, be sure to purchase such a positive rug.

5. Do exercises for your arms for the whole hour or even two hours. It doesn’t matter which one: from the well-known “We wrote, we wrote, our fingers are tired” to snapping fingers - as long as it lasts longer.

6. If you don’t feel comfortable using a mouse, use a special hard medical bandage that also supports your wrist. It can be purchased at an orthopedic salon or at a pharmacy.

7. You need to move the mouse with just your fingers, and not with each hand, especially with the support of your shoulder. Hold mouse hold the edges with your huge finger and little finger, place your index finger on the left button, your middle finger on the wheel, and your ring finger on the right button.

Video on the topic

Pay attention!

If carpal tunnel syndrome is no longer making itself felt, but is really worrying, go to the doctor immediately and do not delay treatment.

Useful advice

Learn to use the mouse with both hands. Changing the position will help avoid pain. In addition, it is suitable for developing coordination and posture. You can easily change the functions of the left and right mouse buttons in the settings on the control panel.

Sometimes it is necessary not only to assemble cabinet furniture, but also to disassemble it in order to transport it to another place. You can disassemble the table if you have the necessary tools and carefully study its design.

You will need

- – flat screwdriver;

- - a huge Phillips screwdriver.

Instructions

1. When starting work, find all the attachment points for the tabletop and legs. The normal fixing elements are located under the tabletop. It is attached to the legs, which can be connected to each other by transverse strips.

2. If the table is combined with another table or with a “corner”, first unscrew the screws (or screws) that hold the ties. Ties have the form of brackets or rectangular plates.

3. Remove the ties that connect the tables. This way you will separate the table from consoles or other furniture.

4. Loosen the tabletop fastening elements. When it is no longer secured, proceed to remove it from the table legs.

6. Place all fasteners (accessories) in a bag and tie them to the boards of the disassembled table, so that if you move, the polished furniture will not be scratched.

7. Take a flathead screwdriver or a large Phillips head screwdriver to remove the table top. With the help of these tools, turn the drums counterclockwise (four extravagant ties). Maintain a rotation angle of about 180 degrees (approximately half a cycle, no more). The eccentrics are located on the inside of the legs closer to the tabletop itself.

8. Typically, such screeds have an arrow pointer. Therefore, when turning the drum counterclockwise, make sure that this arrow points sternly upward. This location indicates that the ties are loose. Using this method, unlock all four ties that are located on the table legs.

9. One leg can have two attachment points, which can be hidden under a decorative overlay to match the color of the table. Therefore, before turning the tie, remove the small plastic circle (decorative element).

10. In order to separate the table legs from the connecting transverse board, point the arrows on the eccentrics directly towards the table legs, bring them into a horizontal position. Turn the ties counterclockwise.

Useful advice

On a piece of paper, draw up a diagram for disassembling the table to make it easier to assemble it in a new place.

Wireless devices are becoming more and more popular among users, and most definitely wireless mice. Most often they can be seen among owners of laptops, although in some cases also among users of desktop computers. After unpacking, many customers of wireless mice wonder: where to put the batteries?

Instructions

1. First of all, unpack the contents of the box and take it out mouse. Please note whether the kit includes brochures or instructions. It turns out, take it mouse in your hands and look attentively. Usually the manufacturer makes a battery compartment at the bottom of the mouse, but in rare cases it is located primitively in the middle. If the compartment is located at the bottom, then pry it with something sharp or, if there is a “tongue,” press it. Insert the batteries and close the cap.

2. To gain access to the compartment, you need to click on the upper part of the mouse body, and then slowly pull it towards you. Don't worry: the mouse will not break, only the moving part will be removed. Insert the batteries and close the lid, the main thing is not to break the teeth that are inserted into the grooves on the case. The main locations of battery compartments in mice are discussed. If your wireless mouse does not have a compartment in the 2 indicated places, then read the instructions that come with the kit. The instructions can also always be downloaded on the manufacturer’s official website.

3. When using a wireless mouse, it is occasionally necessary to completely disassemble its case - for example, to clean it from dust or to troubleshoot problems. Start with the screws. Look carefully at the bottom of the mouse: remove the stickers and legs, since the largest number of screws are hidden under them. Unscrew them and carefully remove the upper part of the housing. On some “sophisticated” mice, the upper and lower parts of the case are connected by a special cable, and if it is torn off, you will have to take it for repairs. It makes no sense to unscrew all the insides, since every dust will already be clearly visible. The screws can be pre-numbered so as not to get confused when assembling the mouse. The legs can be glued back with double-sided tape or cleaned in advance and glued with silicone glue.

Useful advice

The mouse is assembled in the reverse order. The board, scroller and cover are put in place. If there are latches, make sure that they all click into place.

Good day, dear readers!

Mouse and keyboard are among the most used peripheral devices. This is why these devices, especially mice, quickly develop all sorts of operational problems. This may be poor response of buttons, double pressing of buttons with a single click, problems with the scroll wheel (it moves jerkily), problems with the system detecting the device. Most problems are caused by mechanical wear and dirt getting inside the mouse body.

If your mouse buttons do not work well when you press them or a double click works, then the likely reason lies precisely in mechanical wear. All elements of the manipulator are made of plastic and with frequent use they quickly wear out and wear appears. When you click, the mouse button stroke is no longer sufficient for the button to work reliably.

1. Mouse button doesn't work

A) Detecting wear is fairly easy. You should disassemble the mouse; to do this, just unscrew one or two screws from its bottom side. Mouse buttons can have different designs, but for the most part they are a plastic part of the top cover (or a separate element), which, through a plastic lever, acts on a button soldered on a printed circuit board. It is on this plastic lever that the wear appears. To restore the functionality of the mouse, you need to clean the surface of the lever using a file or sandpaper, ensuring a flat surface. Also pay attention to the reliability of the mounting of the printed circuit board and the quality of the solder joints of the button.

b) Let’s not go far from this problem and will analyze in more detail the quality of the button itself, or in other words the mikrik, but if the problem lies in the mikrik itself, then we can simply solder it and any old mouse can become a donor or purchase it in a special store, if there is one available nearby. To re-solder the microphone, we heat the legs of the microswitch and pry it with a knife (or pull it with your fingers from the back side) and pull out the switch, this must be done simultaneously and quickly, ( When soldering, it is advisable not to overheat the button). After desoldering the board, it is necessary to clean the holes from old solder so that you can easily insert and solder the working mic.

V) Let's look at an option in which we could do without a soldering iron. To do this we need to disassemble the button, this is not difficult to do. Use a thin screwdriver or a needle to pry up the cover, first from one side, then from the other, and remove the cover. After removal, a button will fall out of the cover, which it is advisable not to lose. The problem is that over time the tongue on the record begins to sag, we need to bend it slightly. We assemble the button and check the mouse for functionality.

2. The mouse wheel does not work (it moves jerkily)

To solve this problem, we, of course, need to disassemble the mouse, this time we will work with a wireless pointing device. And so we unscrew the screws on the bottom of the mouse and remove its upper part, then unscrew all the screws that secure the board to the bottom of the mouse body. Now that the board is unscrewed, lift it and carefully pull the wheel out of the scroll sensor. So we got to the faulty element.

The reasons for the malfunction may be as follows: the mouse scrolling mechanism has become loose, with such a malfunction we could simply press the four antennae with pliers and everything would seem to have been fixed, but with such a repair, at best, your mouse would have lived for another month. The malfunction could also be caused by dirty contacts of the rotating mechanism. So the next thing we need to do is disassemble the scroll sensor. We bend the four antennae that hold the insides of the sensitive element

and bend back the part that is soldered into the board with three legs

after which we pull out the drum, inside of which there are contacts.

That's it, the disassembly is complete, now all that remains is to remove it and put it back together. Take a cotton swab, soak it in some alcoholic liquid and wipe the contact surface. Now we put the whole mechanism back together in reverse order. After assembly, it is necessary to strengthen the mouse scrolling mechanism; to do this, you need to install a U-shaped bracket made of a metal plate.

Let's assemble the mouse and see the result of our labors.

3. PProblems with device detection by the system

Software errors in the operation of the manipulator are also possible. If possible, you should first check the operation of the mouse on another computer or laptop; if errors also appear, then most likely the reason is in the hardware of the manipulator. Software errors are possible, most likely with game controllers that require the installation of additional drivers or software; you can also update the drivers or hardware configuration in the device manager. With standard devices, software problems are very rare. But, nevertheless, if problems arise, try to find and install the appropriate driver. Also check that the USB or PS/2 port controller is working properly. You may need to update your motherboard driver to resolve the issue.

4 In addition to everything, there are also such malfunctions

1. Also, the reason for poor operation of the buttons and scroll wheel is ordinary dust, or rather the dust that has accumulated inside the mouse body. After several months of use, a lot of dust, lint, hair and other contaminants accumulate in the mouse. All this is reflected in the operation of the scroll wheel. The wheel becomes stiff and scrolling may be uneven. You should disassemble the manipulator and carefully remove all dust and other dirt particles. The plastic body of the mouse can be wiped with damp wipes or rinsed in warm water. Avoid getting moisture on the printed circuit board elements, and if this happens, do not use the mouse until the moisture has completely dried (preferably within 24 hours).

2. Another cause of problems with the mouse may be a broken wire. Due to vigorous use of the manipulator, thin wiring often breaks at the point where it is soldered to the mouse board or on the connector. In this case, you should also disassemble the mouse and look at the place where the wires are soldered, and also check the connector. If a broken wire or a soldered connector leg is detected, the fault must be corrected. If you do not have sufficient skills, then contact a specialist.

3. The next problem with the mouse may lie in the connector connecting the device to the computer. Modern manipulators are connected via a USB connector, but there are still devices on sale for connecting via a PS/2 port. It is this port that often causes various malfunctions. It's all about unreliable contacts and the ability of thin connector pins to easily bend and break off. If the contacts are wrinkled, they should be carefully aligned. In this case, you should be careful not to damage adjacent contacts. With a USB connector, problems with poor contact are less common and occur when the device is connected to a heavily dirty port.

Other errors in the operation of the mouse are most likely associated with the output of the device’s radio elements, and in this case, repairing the mouse yourself without special equipment is problematic. All that remains is to buy a new mouse.

Good luck to everyone and see you for the new renovation.