What to do if the disk dia is larger. Disc parameters, markings. Diameter of the central hole for Niva

Many car owners are familiar with the feeling of frustration when the wheels they saw in the window and really liked do not fit the car. And it’s even more offensive when all their parameters are as needed, except for one, and most often in such a situation the diameter of the hub hole turns out to be inappropriate. Is it always possible to eliminate this issue, and what should you do if the DIA turns out to be the wrong size?

1. What should the central hole be?

Before looking for workarounds that will allow you to place a non-original disc on the hub of your car, let’s clarify what exactly the abbreviation DIA means. This is an abbreviation for the word “Hub Diameter”, which literally translates as “landing diameter”. This is the name of the size of the central hole in the disk, corresponding in diameter to the seating belt on the hub.

Before choosing wheels for your car, compare the DIA with the hub size

2. If the CO is more than necessary

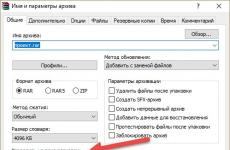

Enlarging the central hole on the disks is quite acceptable, but with one condition - if you find an adapter the right size. What is it? This is an insert - a centering ring made of metal or plastic, the outer diameter of which corresponds to the hole on the disk, and the inner diameter corresponds to the hub diameter. Therefore, two sizes are always indicated on rings, which is what we see in the photo.

![]()

![]()

Sometimes the difference between these circles is only 1 mm, and the car owner has a desire to put on these rims and drive like that. What does this mean?

If the disk does not fit tightly to the hub, the wheel is forced to be centered by fastening elements - bolts or studs. They have to take on all the shock loads, as a result of which they become deformed or simply break.

If the wheel is unevenly fastened, the disk moves from its axis, radial runout appears, which cannot be eliminated using a balancing machine. At the same time, at a certain speed the steering wheel may shake, causing unpleasant vibration of the body, which can contribute to spontaneous unscrewing of the wheels.

But even if this does not happen, the car will be subject to accelerated wear of the steering rack, shock absorbers, ball joints and all rubber bands on the suspension. And this is not to mention the premature and uneven wear of the tread on tires, which are already quite an expensive pleasure for every driver.

![]()

![]()

To avoid such an impressive number of problems, it is worth looking for either discs with the correct hub hole, or adapters, the price of which is a maximum of 150 rubles. per piece (if aluminum) and 50 rubles if plastic. Moreover, normal stores that sell discs most often also have an assortment of centering rings on sale.

In addition, many manufacturers purposefully produce universal wheels with double drilling that can be installed on different cars. In this case, the central hole has the largest possible diameter, and the transition to a smaller one is provided precisely due to the hub adapters.

Note: These options are mainly offered for passenger cars with a hub size not exceeding 73 mm. There is no such thing as being able to remove the rims from a large SUV and put them on a small sedan.

3. If the hole on the disk is smaller than the hub

It’s stupid, of course, to buy obviously unsuitable wheels for a car. Why grind wheels if you can easily find the original size? But sometimes you have to.

Situations are different. For example, the car model is quite rare, and wheels with the required parameters simply cannot be found in stores. Or let’s say a person cannot afford to buy a new kit, but there is a suitable option on the market, but it just doesn’t fit on the hub of your car.

Note: To determine the exact difference, you need to use a caliper and measure the diameter of the hub and the diameter of the hole on the disk, as shown in the photo.

![]()

![]() Before choosing used wheels, measure the hub hole

Before choosing used wheels, measure the hub hole

4. Self-boring of steel discs

In this case, car owners often turn to turners with a request for boring, or are looking for an answer to the question: how to grind the center of a cast wheel yourself. Of course, this is not a job for the garage, because it is necessary to remove a layer of metal, and this must be done precisely. If you remove too much, you will ruin the discs.

The maximum that can be done at home is to remove 1-2 mm if the discs are iron. To do this, you can use a drill with a flap wheel adjusted in diameter to the disk hole.

![]()

![]()

![]()

![]()

![]()

![]()

But this is a cliche. Is it possible to sharpen alloy wheels from the inside? We will answer this question further.

5. Grooving the cast disc

In general, it is undesirable to do this, since the strength of the disk at the point of its attachment to the hub when mechanical impact weakens. It may simply crack when moving. If you do sharpen it, then do it very little, and it is better to do it in a properly equipped workshop.

In this case, the disk is placed on the table of a jig boring machine. There are pins in its grooves and a hub is put on so that the disc can be properly fixed.

![]()

![]()

For rough alignment, a cone is installed, which is lowered into the center of the disk, after which nuts are screwed onto the studs.

![]()

![]()

Then the cone is removed and a micrometer is placed in its place, with the help of which a more accurate position of the disk on the table is determined. That is, full alignment is carried out.

Next, the cutter is installed and the disc groove begins. A bore gauge is prepared and fixed to the size to which the hole needs to be expanded.

![]()

![]()

The initial adjustment is carried out approximately, the exact value is achieved in the final.

![]()

![]()

The finished, bored discs will only have to be tried on.

![]()

![]()

The work of boring holes for four disks will cost about 3000-3500 rubles. If you consider this amount, coupled with the cost of used disks (and even more so new ones), to be quite acceptable, it’s up to you. But you will have to regularly monitor their condition, because a small crack around the central heating center can grow into a big problem.

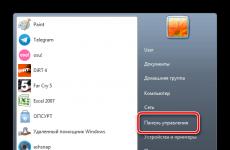

5. Hub holes and bolt patterns for cars from different manufacturers

When buying discs in a store, there are no problems finding out their size. All parameters are indicated on the price tag, and if not, you can read it on the packaging box. If the original size is not on sale, the consultant will always tell you from which car the rims are suitable for your car.

Basically, a car owner may need such information if he purchases wheels second-hand. How to choose used alloy wheels will be discussed below.

6. Models and sizes. Parameter table.

Since when selecting wheels you need to focus not only on DIA and radius, but also on bolt pattern and offset, we present a table with the main parameters of disks for the most popular cars. It will show which cars the wheels fit for a particular car.

Car brand | Model | Basic parameters | |||

| DIA | PCD | ET (from and to) |

|||

| Alfa Romeo | 145,146; 155; 164 | 58,1 | 4×98 | 35-42 | |

| Alfa Romeo | 75, 156, 164 2.0 turbo, GTV, Spider | 58,0 | 5 x 98 | 28-30 | |

| VAZ | 2101-2107 | 58,6 | 4×98 | 25-32 | |

| VAZ | 2108-all cars | 58,6 | 4×98 | 35-40 | |

| Fiat | All | 58,1 | 4×98 | 35-42 | |

| Audi | A6, A8, S6, Quattro, Audi 200 | 57,1 | 5×112 | 35-42 | |

| Audi | A3 96-03, S3 98, TT 99 | 57,1 | 5×100 | 38-42 | |

| Audi | Audi 80, Audi 100 | 57,0 | 4×108 | 35-42 | |

| Seat | Ibizia; Leon Cupra R; Toledo II | 57,1 | 5×100 | 35-45 | |

| Skoda | Fabia, Octavia | 57,1 | 5×100 | 35-42 | |

| Chevrolet | Corsica, Beretta, Cavalier | 57,1 | 5×100 | 35-40 | |

| Chevrolet | Camaro, Corvette, Lumina, Blazer | 70,5 | 5 x 120 | 38-50 | |

| Chevrolet | Tahoe | 78,1 | 6 x 139.7 | 31 | |

| Volkswagen | Golf IV, Bora; Golf III 5 | 57,1 | 5×100 | 35-42 | |

| Volkswagen | New Golf V; Passat 5; transporter; Phaeton, Sharan, Touran | 57,1 | 5×112 | 40-45 | |

| Volkswagen | Corrado 4, Golf I and II, Passat 4, Polo | 57,1 | 4×100 | 35-42 | |

| Volkswagen | Touareg | 71,6 | 5×130 | 50 | |

| Citroen | C8, Evasion | 58,1 | 5×98 | 25-38 | |

| Citroen | Berlingo, C2 - C5, Saxo | 65,1 | 4×108 | 15-25 | |

| Saab | 9, 900, 9000 | 65,1 | 4×108 | 35-42 | |

| Volvo | 850 4 Stud | 65,1 | 4×108 | 25-42 | |

| Volvo | 7 & 9 Series | 65,1 | 5×108 | 15-25 | |

| Volvo | 850 5 Stud, 960, C70 & S70, S60, S80, V70 | 65,1 | 5×108 | 35-42 | |

| Volvo | S40/V40 | 67,1 | 4×114.3 | 35-42 | |

| Ford | Escort, Fiesta, Scorpio, Mondeo | 63,4 | 4×108 | 35-42 | |

| Ford | Focus, C-MAX, New Mondeo, Taunus 4 | 63,4 | 5×108 | 38-45 | |

| Ford | Galaxy | 57,1 | 5 x 112 | 42-45 | |

| Ford | Explorer, Maverick | 100.0 | 6 x 139.7 | -3-0 | |

| Honda | Civic/CRX, Jazz 01 | 64,1 | 4×100 | 35-42 | |

| Honda | Accord / Prelude, Civic 1.8 / Aerodeck | 64,1 | 4×114.3 | 38-45 | |

| Honda | Accord 03, CR-V, HR-V, Integra, Odysee | 64,1 | 5×114.3 | 38-50 | |

| Rover | 600, 800 | 64,1 | 4×114.3 | 35-42 | |

| Rover | 200, 400, 25, 75, Steetwise | 56,1 | 4×100 | 35-42 | |

| Hyundai | Accent, Elantra, Sonata, Matrix | 67,1 | 4×114.3 | 35-45 | |

| Hyundai | Santa Fe, Trajet | 67,1 | 5×114.3 | 35-45 | |

| Hyundai | Getz | 54,1 | 4×100 | 35-45 | |

| Kia | Carens, Magnetis | 67,1 | 4×114.3 | 35-42 | |

| Kia | Rio | 54,1 | 4×100 | 35-42 | |

| Lexus | All | 60,1 | 5×114.3 | 38-45 | |

| Toyota | Avensis, Carina, Celica | 54,1 | 5×100 | 35-42 | |

| Toyota | Avensis Verso, Camry, MR2 W2, Picnic, Rav 4, Sienna, Supra | 60,1 | 5×114.3 | 35-42 | |

| Toyota | Corolla 02, Corolla Verso, Prius, Starlet, Yaris | 54,1 | 4×100 | 35-42 | |

| Renault | Clio, Kangoo, Megane, Scenic, Super 5 | 60,1 | 4×100 | 35-42 | |

| Renault | Espace, Laguna 01, Scenic RX4, Vel Satis | 60,1 | 5×108 | 38-45 | |

| Renault | Trafic, Twingo | 71,2 | 5×118 | 38-45 | |

| LADA | PRIORA, KALINA, GRANTA | 58,6 | 4×98 | 33-38 | |

| LADA | LARGUS, VESTA, XRAY | 60,1 | 4×100 | 45-50 | |

| LADA | Niva, 4X4 URBAN | 98,5 | 5×139.7 | 15,35,58 | |

| Mazda | Premacy, Tribute, Xedos, 626; 3; 6 | 67,1 | 5×114.3 | 35-45 | |

| Mazda | 323, Demio, MX3 | 54.1 | 5×114.3 | 35-45 | |

| Mercedes | C Class, CL Class, CLK, E Class, S Class W140, SL Class | 66,6 | 5×112 | 35-42 | |

| Mercedes | A Class, | 66,6 | 5×112 | 45-50 | |

| Mercedes | M Class ML430, S Class W220 | 66,6 | 5×112 | 98-99 | |

| Mitsubishi | Carisma 1.6, Colt, Lancer | 56,1 | 4×100 | 38-45 | |

| Mitsubishi | Carisma 1.8, Galant, Space Star, | 67,1 | 4×114.3 | 38-45 | |

| Mitsubishi | Outlander, Pinin, Space Wagon | 67,1 | 5×114.3 | 38-45 | |

| Nissan | Almera 99, 100 NX, Micra, Sunny | 66,1 | 4×100 | 35-42 | |

| Nissan | Almera 00, 200 SX, Primera | 66,1 | 4×114.3 | 35-42 | |

| Nissan | Almera Tino, Maxima, Serena, X Trail | 66,1 | 5×114.3 | 35-45 | |

| Peugeot | 106, 205, 206, 306-406 | 65,1 | 4×108 | 15-20 | |

| Peugeot | 605, 607 | 65,1 | 5×108 | 35-42 | |

| Subaru | Forrester, Impreza, Legacy | 56,1 | 5×100 | 42-50 | |

| Subaru | SVX | 56,1 | 5×114.3 | 42-50 | |

| Opel | Astra, Astra 4, Corsa 00, Mervia, Tigra, Vectra 4 | 56,6 | 4×100 | 35-45 | |

| Opel | Astra 5, Astravan, Vectra 5, Corsa 1.7 CDti, Vectra/Sigrum, Zafira | 65,1 | 5×110 | 35-45 | |

| Opel | Sintra | 70,3 | 5×115 | 35-45 | |

| Opel | Vivaro | 71,2 | 5×118 | 40-45 | |

| BMW | BMW 3 series (E30) | 57,0 | 4 x 100 | 15-25 | |

| BMW | BMW M3 (E30), BMW 3 series (E36), BMW 3 series (E46), BMW 5 series (E34), BMW 7 series (E32) and (E38), BMW 8 series | 72,5 | 5 x 120 | 18-20 | |

| BMW | BMW 5 series (E39) | 74,0 | 5 x 120 | 18-20 | |

| Daewoo | Espero, Lanos, Nexia | 56,5 | 4 x 100 | 38-42 | |

| Daewoo | Matiz | 69,1 | 4×114.3 | 38 | |

Although not all makes and models of cars are listed in the table, we hope that this information will help you navigate the parameters. But before how to choose wheels for a car, it is necessary to accurately measure the hub hole on them.

![]()

![]()

The offset (ET) can be read on the back of the disc - where exactly is shown in the photo with an arrow. As for PCD, it will have to be calculated using a formula, depending on the number of holes. You can read more about this on our website about

A pressing question among motorists: “what is DIA on disks?” To ensure continued operation vehicle, must be done correct selection wheel structures. After all, safety depends on their properties traffic. If all indicators of the wheelbase are violated, the mechanism deteriorates, and the vehicle’s handling also deteriorates.

When it comes to purchasing new components, it is quite difficult to do without expert advice. When choosing designs for their car, many are not even familiar with the basic parameters. Therefore, before installing components on your car, you need to study all the vehicle indicators specified in the technical passport of the manufacturer.

DIA value

Their list primarily includes offset, PCD, DIA, product width, etc. Quite a few important role wheel marking plays. Its indicator is usually indicated on the label or in the technical data sheet. This information displayed for all types of structures in a standard format.

- A is the diameter of the central hole of the disk;

- B - width;

- ET - the offset of the structure is used to determine the distance between the space where the rim is applied to the hub and the internal sphere of the structure.

The mating plane is the base that connects the wheel rim to the vehicle hub. When choosing designs, you should not be guided only by the external data of the components. Otherwise, you can worsen the technical condition of the vehicle, as well as its handling on smooth asphalt or off-road.

Disc overhang is divided into positive, negative and zero. In the latter option, the mating plane of the product is determined between the middle of the structure. If they coincide with each other, then the wheel type is considered zero.

Sometimes it happens that the overhang indicator is smaller, then the structure will stick out unsightly from the outside of the vehicle. However, some motorists like wide components. Therefore, they choose the first option. In the second case, everything looks different: the higher the ET value, the tighter the structure fits inside the car.

Pay attention!

The width of the structure may differ from the disc offset value. Many manufacturers of automotive components indicate in the technical data sheet for the car that wheels with a larger width have a lower offset indicator.

PCD means hole center circle diameter rim. This indicator determines the location of the wheel design mounting holes.

Often, beginners and even experienced drivers cannot decipher the symbols indicated on car wheels. To avoid mistakes when choosing tires, you need to carefully study all the indicators. What is DIA on disks is the diameter of the central hole. On many manufactured alloy wheels, in order to give the car a presentable appearance, the diameter of the central hole DIA is made larger. To correctly select the size of a car hub, experts recommend choosing an adapter ring or bushing.

Design mounting hole

Product mounting hole

Product mounting hole

The landing diameter of the wheel rim is as follows - 7.5 j x16 H2 5/112 ET 35 d 66.6:

- 7.5 - width of the structure.

- J is a feature of automotive designs.

- x - inseparability of wheels.

- 16 - landing diameter.

- H2 - two protrusions.

- 5/112 is determined by the number of mounting holes for bolts or nuts, and 112 serves as the diameter of the circle.

- ET 35 - product size is 35 mm.

- d 66.6 - diameter of the central hole.

Is it possible to install components with a large central hole?

Is it possible to install structures with a large CO

Is it possible to install structures with a large CO

The question of what effect CO has on car rims remains relevant both among beginners and experienced drivers. The disc, which has a universal central diameter, is sold in all stores, as well as online resources. Modern developments, which have a large central hole, fit many models.

The main reason why original automobile developments are noticeably more expensive than even the highest quality non-original analogs is the requirements of automakers.

What is a central heating center on car wheels?

What does CO mean?

What does CO mean?

Many people are interested in the question of what the central hole of the disk is. This indicator determines many parameters. The vehicle's handling on icy/wet asphalt depends on this value. When choosing wheels for a car, DIA is defined as a characteristic of the wheel. Sometimes manufacturers may designate this indicator as D. Some car owners buy large mounting bolts that are not installed on the structure. All these nuances should be taken into account to ensure the safety of the driver/passenger.

What to do if the CO of the structure is greater than the CO of the hub

Difference in CO size

Difference in CO size

The diameter of the central hole of the disk must match the parameters of the diameter of the landing cylinder where the hub is located. For recent years many manufacturers began to produce identical designs for several car brands at once. Therefore, when purchasing new components for a vehicle, you need to determine the compliance of this parameter.

What is a wheel hub hole

For each machine there are acceptable parameters that must be taken into account before purchasing accessories or components. For example, the parameter of wheel landing diameters plays an important role. Indicators may differ significantly from each other. The exact value can only be determined by looking at the label.

Hub hole development

Hub hole development The variety of diameters of the central hole confuses many buyers. A minor difference may affect the technical condition of the vehicle. For example, most often the difference is only 0.1 mm.

Motorists are often interested in the question of what Dia is in the parameters of car rims. The above-mentioned requirements of wheel product manufacturers for automobile wheels produced under their brand concern not so much appearance, how much quality they have.

Thus, when determining the PCD, all characteristics of the vehicle must be taken into account. Basically, tire mounting holes go on sale at a high rate.

Reading time: 11 minutes.

In order to choose the right wheels for a car, you need to know about such things as: types of disks, disk diameter, disk mounting diameter (dia), rim width, wheel offset, HUMP, PCD, maximum load that the disk can withstand. Knowing all these aspects, you can easily choose the drives that suit you best.

Types of disks

Car wheels can be classified into three main types, or categories: stamped, cast and forged. Of course, you can write a separate entire material about each specific type, but here we will look at the main nuances and differences.

Stamped discs

The first type of discs is stamped. They are the cheapest and, perhaps, the most common: after all, these are the same rims that we are used to seeing on stock and even mid-range trim levels of many budget cars, both domestic and foreign. And sometimes even the cheapest and most basic versions of class D and E cars. The same ones that are often covered with decorative plastic caps. They are made of steel and painted with enamel. They have their own advantages, and among their advantages, in addition to the lowest cost, is that they can be easily and quickly restored, and they are also distinguished by high repairability, among other types of disks. The secret lies in the fact that “stampings,” as they are popularly called, do not break when struck or severely damaged, but crumple, and as a result, due to their origin, they are easy to repair, because they are a whole stamped piece of metal. But there are also disadvantages - the other side of the coin, again, due to the features. So, the main disadvantage of these wheels is their high weight and design, or rather the lack of the latter: after all, for manufacturers they are only a purely functional product.

Alloy wheels

The second type is alloy wheels. As statistics show, although they sometimes lag behind their stamped counterparts in popularity, they almost always constitute worthy competition. A different manufacturing technology is used here. For the manufacture of such disks, not steel is used, but a lighter alloy, usually aluminum. Unlike “stamps”, due to the introduction of manufacturing technologies, engineers and manufacturers have a lot of room for imagination: alloy wheels can have a wide variety of shapes. And not only this - combined with a lighter weight than stamping, this guarantees their popularity. The cast disc has a grainy internal metal structure.

“Casting” also has some disadvantages: these include their higher cost than “stamping”. As well as their lower maintainability. The fact is that, due to their origin, alloy wheels do not wrinkle after strong impacts or when damaged, like “stamps,” but crack. Although it is worth noting that special technology for welding restoration and rolling has been used for several decades, even so it is impossible to completely guarantee the restoration of the original qualities and properties and their preservation after such repairs.

Forged wheels

And the third common type are forged wheels. This type is the highest quality and most expensive option of all of the above. In their production, hot die forging is used, and thanks to this method, the best internal structure of the metal is guaranteed and, from which it follows, a combination of the highest strength with the lowest weight of the disk. It should be noted reverse side this method– not so widespread products and high cost. They are known among lovers of expensive, high-quality wheels (usually for the same cars) and fans of tuned cars.

In addition to all the above types, there is also a so-called prefabricated disk. However, this is already exotic; they are made using special technologies from ultra-light and ultra-strong metals (which means they are ultra-expensive), and even other materials, say, composites, and we will not consider them here. As a rule, the average car owner opts for either inexpensive, but visually boring “stampings”, or at least more expensive, but much more pleasant-looking alloy wheels.

Disc diameter

In two words, this parameter of the disk is obvious (visual): in other words, it is its circumference, which is commonly counted throughout the world in inches. It is usually denoted by the letter R: for example, the R14 and R18 disks have a diameter of 14 and 18 inches, respectively.

Particular attention should be paid to the fact that the letter R itself has nothing to do with the diameter, and comes from the designation of the properties and parameters of the tire, where it is also common to mistakenly use the word “radius” in the designation. However, in reality, this only implies the tire diameter.

In fact, in the case of tires, it is customary to designate the marking using R - due to the type of cord construction. Meaning radial, the concept is a relic of the past. Once upon a time, in addition to radial tires, there were also diagonal tires, and for the disk the use of this marking is practically no longer relevant. As a result, such an erroneous use of the word “radius” in the designation “diameter” with the accompanying letter R is so deeply rooted in speech that not only car owners, but also many sellers and servicemen, and disc service stations use it by default.

What possible diameters exist for discs for specific model cars that are acceptable can be found in their operating manuals. This is also evidenced by the stickers that are located in the doorways, which, in addition, also contain data on the recommended tire pressure. When you are going to buy disks, you should know that their diameter must necessarily coincide with the mounting diameter.

You should not go too far with the maximum permissible disc diameter declared by the manufacturer. Unless, of course, you are involved in complex tuning of cars, especially suspensions. The fact is that discs that have too large a diameter have a negative effect on the chassis. Because of this, the parameters of the suspension and its usual operating conditions change. The load also increases not only on the suspension parts, but also on its attachment points with the body, and the wear of the chassis accelerates. Also, they often have geometric incompatibility. Even if everything is correctly selected and configured, especially after proper tuning of the car, you should know that the larger the diameter and width of the disk, and especially the lower the profile of the rubber, the greater the degree of discomfort when driving on bad roads. And even on uneven or rocky road surfaces. Also, another problem is that you have to slow down a lot in front of speed bumps and, especially when crossing tram tracks. Or you should take into account the nuances of tuning on the contrary - that is, when the diameter of the disks has not increased much (although it may have increased), but the rubber has a high profile. That is, unlike the previous option, there are some advantages here - bolder and faster crossing of the same tram tracks and speed bumps and other obstacles, and confident movement off-road, and a more comfortable and noble “gait” on bad roads.

What will happen if you don’t tune the suspension, no matter a crossover, a car, or even a real “rogue”? Similar problems listed above will appear related to the chassis, which are also relevant here. Also, low-profile tires guarantee more precise and composed behavior, confident cornering at high speed, and good grip on the road. high speeds on the highway. But with high-profile wheels, it’s just the opposite – with them the center of gravity often increases, and reactions to the steering wheel are more blurred and delayed, and at high speeds stability is inferior even to stock wheels.

True, it is worth knowing that if you change the diameter of the disks within the recommended permissible value, as indicated in the manual, an inch more, then everything for the chassis and body will take place with virtually no significant consequences.

DIA

Another important parameter is DIA, which is the diameter of the central hole. More precisely, the diameter of the central hole for the hub.

Rim width

Now let’s look at another important parameter, with which, by the way, everything turns out to be as simple as with the letter “R”, as mentioned earlier. The width of the rims is usually calculated in the same way - in inches. How nice, they designate it with the letter J. For example, 6J, or 7.5J: that is, we have a disk with a width of six or seven and a half inches, respectively.

Data on the width of the disk, as a rule, can be seen in the same special places where its permissible mounting diameter is written. In addition to the geometric parameters for the car, it is important to take into account the width of the rim when choosing tires: they are produced taking into account operation with a rim of a certain width. However, some error is allowed. Let's say that many Russian cars have a factory width of 175 mm, but without special measures and tuning, 185 mm is allowed.

Disc offset (ET)

In short, the offset is the distance, the interval from the mating plane of the disks to the hub to the longitudinal axis of symmetry. To put it simply: the central axis of symmetry is the line that bisects the disk along the aforementioned width. The point where the disk hub comes into contact with it and is screwed to it is called the mating plane.

There are three types of departure: positive, zero and negative. So, in the case when the axis of symmetry is closer to the car, in relation to the mating plane, this is considered a positive offset. If they are on the same axis, then this is considered zero. And the third type - if the axis of symmetry is located further away from the car, compared to the mating plane - then the camber is considered positive. In two words, based on the greater the offset of the disk, the deeper it should sit in the wheel arch. And vice versa - if it is smaller, then based on its size, the disk should protrude outward.

It’s worth considering that offset is one of the rather important parameters. Because it also directly determines how the entire suspension, wheel bearings and their supports, and the attachment point work. If the offset is non-standard (due to the installation of other disks), then this will only increase or decrease the car’s track, which will have an ambiguous effect on handling, and even worsen it, but can also guarantee accelerated wear of the entire chassis and bearings.

HUMP

The concept of HUMP, also known as (H), is also known among us as hump. This is the name given to the ring-shaped ridges on the rim. Thanks to the humps, the tubeless tire does not jump off the rim - this is prevented. Typically, a pair of humps (designated H2) is installed on the wheel. However, there is also a single type (simply - N). In some cases, they may simply not exist at all. Humps belong to one of the following types; flat, asymmetric () and combined. Their designation is FH (from the English word Flat), AN (Asymmetris), and CH (Combi), respectively.

Nowadays, you can only find tube tires that do not have humps on rare cars with retro wheels of considerable age. Although it is possible to install tubeless tires on them. True, the question of the safety of the car when driving and its sealed fit remains open: after all, when cornering there is a very high risk of “taking off your shoes”, since there is insufficient pressure inside the tire.

Also worth noting is ET: this is how the disk is offset. If the overhang is smaller, then based on its value, the more the discs will protrude from the outside of the car. Therefore, what does departure mean? greater value, then the disk will be “recessed” deeper into the car body.

Mounting Hole Diameter (PCD)

Holes are used to attach disks; in other words, this is PCD. It is also known as "bolt pattern", which refers to the diameter of the circle and the number of holes. They are installed on it. This is an abbreviation for the English concept Pitch Circle Diameter and refers to the diameter of a circle. The number of mounting bolts varies, and their number increases based on the increase in the weight of the car model and its maximum speed. As a rule, there are from four to six. However, there are more of them (for example, seven and eight) and fewer (but not less than three). For example, almost the entire modern model range of AvtoVAZ “stands” on the bolt pattern with a value of 4x98-4x100, except for models such as Oka (where 3x98 is used) and the Niva version (where 5x139.7).

It is necessary to comply with the required disc bolt pattern: although it seems that some discs - for example, 4x100 with 4x98, they are interchangeable, this is not so. It would seem that the difference in the diameter of the circle is only a small couple of millimeters. However, in reality they have a very strong influence, or rather interfere with installation. The fact is that only one of the four fasteners will be able to be tightened correctly, and the rest will be offset from the center. And this can cause the wheels to wobble. This problem can be partly solved by using bolts called “floating cone”, but in general the use of discs with inappropriate and unintended bolt patterns should be avoided.

Maximum load that the disk can withstand

This is the static load capacity, measured in kilograms or pounds. Let's say 555 kg per cast disc, this means that four discs are designed to handle a maximum weight of 2,220 kg. If the weight exceeds this norm, then it will be difficult for the discs. Each index value has a maximum load in kg, or pounds, that the tires can withstand in everyday use.

Let's look at the disc markings

For example, let’s look at the marking 9.5×20 5×120 ET 45 Dia 72.6

- 20 is the mounting diameter of the disk, measured in inches;

- 9.5 - disk width, measured in inches;

- 5 - number of holes, measured in pieces;

- 72.6 - hub diameter (DIA), measured in millimeters;

- 120 - bolt-to-bolt distance (PCD), measured in millimeters;

- 45 - disc offset (ET), measured in millimeters.